Consider Space Requirements of Fixings and Ensure Fixing Feasibility

Shows step-by-step how to consider the space requirements of fixing elements when designing pipeline corridor cross sections and at the same time ensure fixing feasibility.

Before you begin

When designing the pipeline corridor cross section, you would like to consider the space requirements of fixing elements and ensure that they are feasible in terms of fixing technology.

Fixing elements are only used to take into account the space requirements of the fasteners in the path and are not generated when paths are generated.

Requirement:

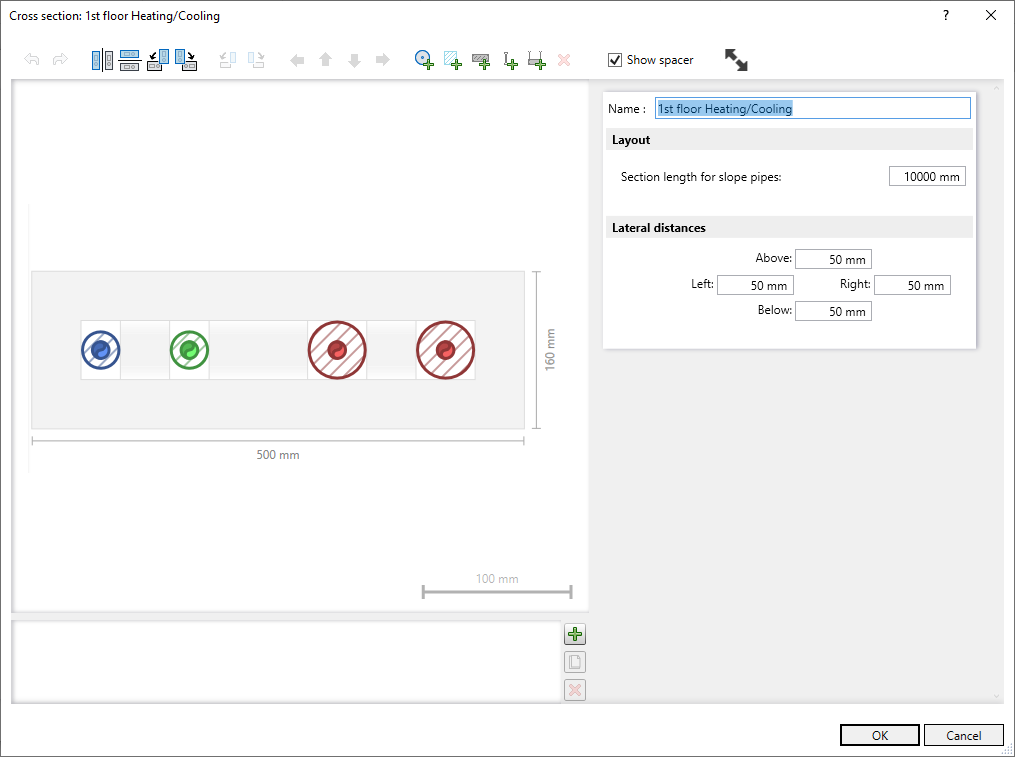

You have completed the requirements planning, placed the necessary equipment rooms in the project and defined the pipe corridor cross section.

Navigate to:

Procedure

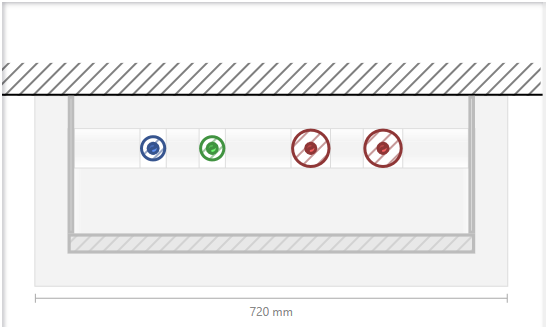

- Click on Insert bracket construction

.

. A bracket construction, consisting of a bracket profile and two bracket threads, comprises the complete layout of the cross-section.

Tip:

Tip:If you want to add bracket constructions to individual pipes/ducts, select the respective pipe/duct before executing the Insert bracket construction function.

Tip:As an alternative to the Insert bracket construction function, you can design a mounting solution tailored to your individual situation by inserting and then positioning individual support threads and profiles.

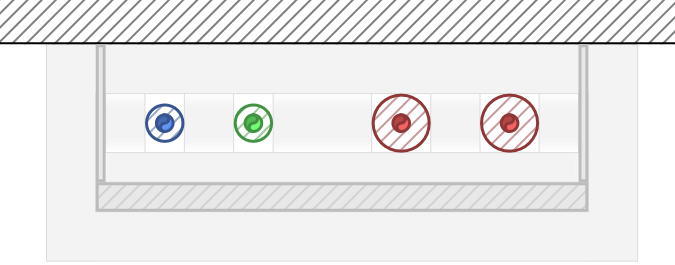

- If necessary, adjust the dimensions of the spacers between the pipes/ducts and the bracket structure.

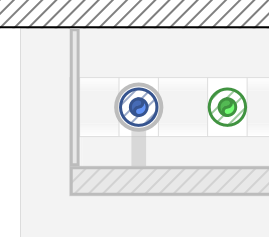

- Select a pipe/duct and specify the Mounting direction under Bracket. The pipe/duct has a threaded rod in the direction of mounting.

- Repeat step 3 for the rest of the pipes.

Results

The cross section considers the space required for the fixing elements and ensures that the layout of the cross section is feasible in terms of fixing technology.

/Edit cross section

/Edit cross section