The LINEAR workflow

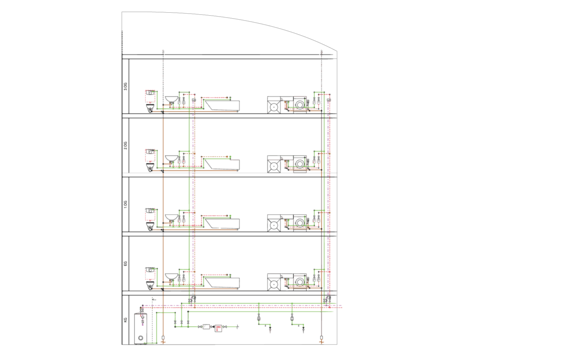

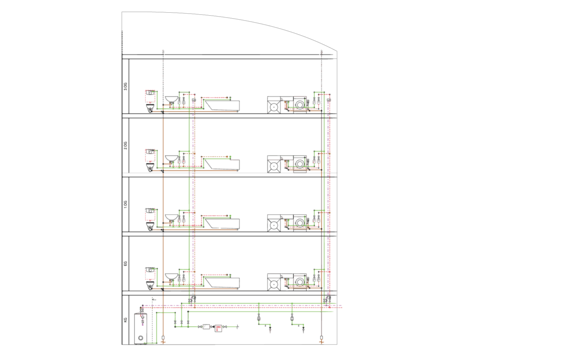

Input:

Supply requirements for the building

Output:

Calculable scheme design

Work steps:

- Create storey table

- Manual scheme creation with toolbars and specific editing commands

- Schema generator for drag and drop and automated drawing

Input:

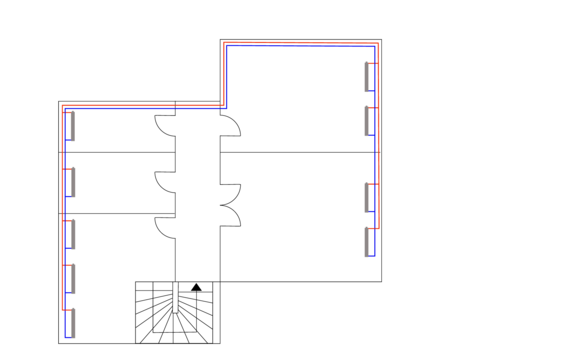

Architectural plan

Output:

Model for further MEP design including levels and rooms

Work steps:

- Referencing DWGs, DXFs or PDFs from the architect

- Create storey table

- Create the architectural model for further construction

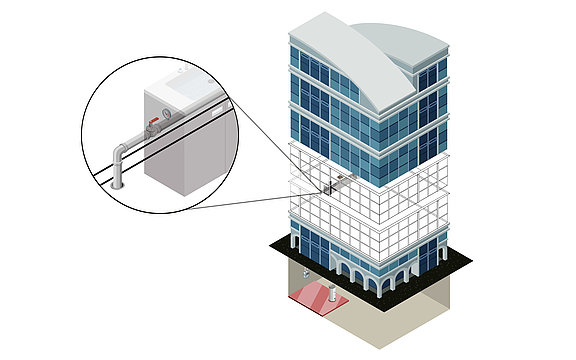

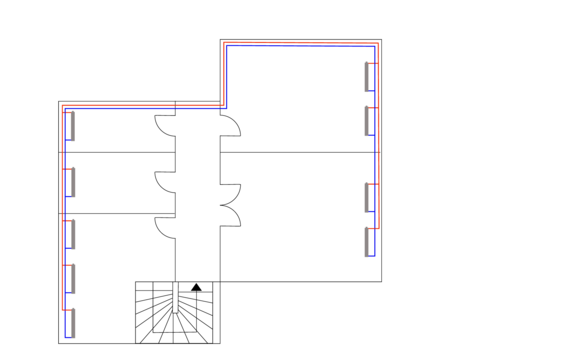

Input:

Model for your MEP design including levels and rooms

Output:

MEP model with gas components

Work steps:

- Selection of gas consumers as neutral components or from the extensive manufacturer CAD libraries

- Easy placement in the model through specific drawing commands

- Integration of system components (e.g. house connections, gas flow monitors, meters, fittings)

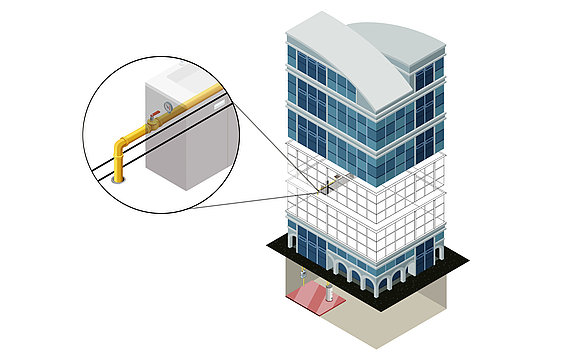

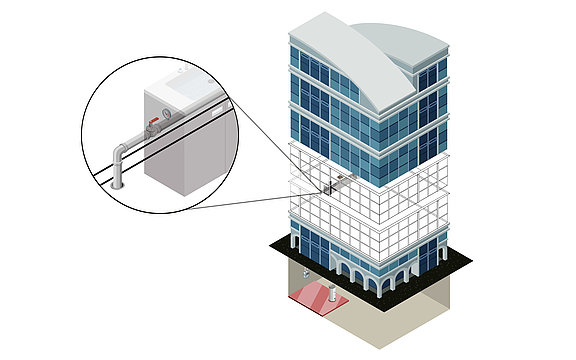

Input:

MEP model with placed gas components

Output:

MEP Model with a calculable network (isometric or floor plan)

Work steps:

- 2D or isometric pipe network design using time-saving construction commands

- Automatic connection of all consumers

- System design in a neutral way or with the help of extensive manufacturer CAD libraries

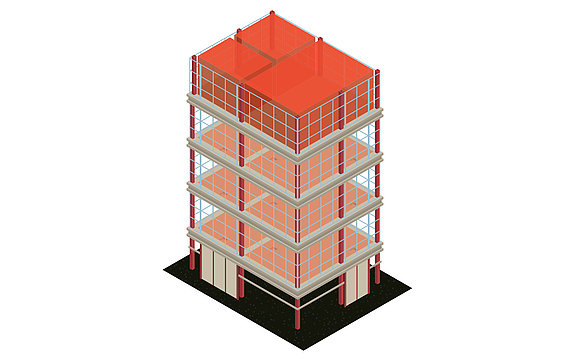

Input:

Architectural model for your MEP design including levels

Output:

Detailed 3D model

Work steps:

- Detailed pipe design

- Automatic routing functions with preview of possible alternatives

- System design in a neutral way or with the help of extensive manufacturer CAD libraries

- Subsequent placement of components with matching transitions and flanges

- Automatic bolting of the entire construction (bolts, nuts, washers) with complete transfer to the parts list

- Pre-define insulation materials and show/hide them with transfer to the parts list

- Real-time collision check

- Manually or automatically assigned item numbers

- Material lists, parts lists with article numbers, sawing lists for pipes, position lists

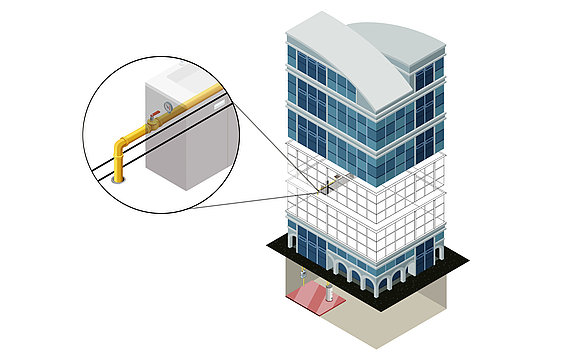

Input:

Scheme, 2D or 3D model

Output:

MEP model with optimized gas system (schematic, 2D or 3D)

Work steps:

- Specification of calculation-relevant specifications (e.g. assignment of pipe materials, gas flow monitors)

- Variant comparison by using verified manufacturer data sets (e.g. pipe systems)

- Calculation of existing networks by fixing single or all dimensions

- Redimensioning of the gas pipe network on the basis of the calculation

- Colored display of all results directly in the model

- Automatic 3D generation during system creation in 2D (step4 - variant 1)

Input:

Calculated and optimized gas pipe network

Output:

Final gas design including model for transfer to the coordination model and calculation results incl. material lists

Work steps:

- Saving of all inputs and calculation results in the model

- Publication of selectable values as component data

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of results and model in all relevant formats

Input:

Supply requirements for the building

Output:

Calculable scheme design

Arbeitsschritte:

- Create storey table

- Manual scheme creation with toolbars and specific editing commands

- Schema generator for drag and drop and automated drawing

Input:

Architectural plan

Output:

Model for further MEP design including levels and rooms

Arbeitsschritte:

- Referencing DWGs, DXFs or PDFs from the architect

- Create storey table

- Create the architectural model for further construction

Input:

Model for your MEP design including levels and rooms

Output:

MEP model with gas components

Arbeitsschritte:

- Selection of gas consumers as neutral components or from the extensive manufacturer CAD libraries

- Easy placement in the model through specific drawing commands

- Integration of system components (e.g. house connections, gas flow monitors, meters, fittings)

Input:

MEP model with placed gas components

Output:

MEP Model with a calculable network (isometric or floor plan)

Arbeitsschritte:

- 2D or isometric pipe network design using time-saving construction commands

- Automatic connection of all consumers

- System design in a neutral way or with the help of extensive manufacturer CAD libraries

Input:

Architectural model for your MEP design including levels

Output:

Detailed 3D model

Arbeitsschritte:

- Detailed pipe design

- Automatic routing functions with preview of possible alternatives

- System design in a neutral way or with the help of extensive manufacturer CAD libraries

- Subsequent placement of components with matching transitions and flanges

- Automatic bolting of the entire construction (bolts, nuts, washers) with complete transfer to the parts list

- Pre-define insulation materials and show/hide them with transfer to the parts list

- Real-time collision check

- Manually or automatically assigned item numbers

- Material lists, parts lists with article numbers, sawing lists for pipes, position lists

Input:

Scheme, 2D or 3D model

Output:

MEP model with optimized gas system (schematic, 2D or 3D)

Arbeitsschritte:

- Specification of calculation-relevant specifications (e.g. assignment of pipe materials, gas flow monitors)

- Variant comparison by using verified manufacturer data sets (e.g. pipe systems)

- Calculation of existing networks by fixing single or all dimensions

- Redimensioning of the gas pipe network on the basis of the calculation

- Colored display of all results directly in the model

- Automatic 3D generation during system creation in 2D (step4 - variant 1)

Input:

Calculated and optimized gas pipe network

Output:

Final gas design including model for transfer to the coordination model and calculation results incl. material lists

Arbeitsschritte:

- Saving of all inputs and calculation results in the model

- Publication of selectable values as component data

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of results and model in all relevant formats

Features

Scheme generator

Create the fastes schemes in the industry with the powerfull scheme generator

- Generate a complete and calculable scheme with drag and drop

- Creating schemes even without CAD experience

- Automatic drawing of scheme

- Define sections and bows

- Easy copy of storeys and pipe runs

- Definition of components (e.g. valves and pumps) already in the generator

- Saving and Importing of existing configurations

Architectural design

- Simple tools for creating walls, windows, doors, roofs, etc. based on multiple document formats such as DWG, DXF, PDF, PNG or JPEG

Construction tools

- Pipe command including system class determination with automatic transfer of media and distances in all view types

- Automatic connection of pipes including necessary transitions (autorouting)

- Automatic T-piece connection

- Pipe offset command to resolve collisions

- Symbols for the trades heating, cooling, gas and architecture (freely expandable)

- Animated hydraulic assistant for the creation of hydraulic circuits

- 2D piping design & 2D manifold generator for detailed design

- Work on 2D and 3D underlays: DWG, DXF, PDF, JPEG, PNG, etc. including design assistant for roof constructions

- Slot and opening design

- Parts lists with short and long texts

- Configurators for radiator, manifolds, tanks and dwelling stations

- Configurator of parallel pipes for routing multiple pipes at once

- Panel heating assistant for circle and pipe laying including construction area editor

- Automatic Labeling and legend creation

Detailed 3D pipe network design

- Pipe design with routing function and pipe classes for creating the fittings with millimeter precision (integrated slope construction)

- Automatic connection of pipes including transfer of media, materials, dimensions and pressure levels.

- Manifold generator for the production of assemblies including pumps and valves and configurators for tanks, plate heat exchangers and other devices

- Insertion of components with suitable transitions and flanges in existing systems

- Real-time collision check

- Automatic 3D generation of calculated single-line drawings

- Connection editor for your own 3D components

- Automatic connection of pipes including transfer of media, materials, dimensions and pressure levels

- Automatic bolting of the entire construction (bolts, nuts, washers) with complete transfer to the parts list

- Predefine insulation materials and show or hide them with transfer to the parts list

- Consideration of deductions for welding seams, gaskets and insertion and bolting depths

- Manually or automatically assigned item numbers

- Material lists, parts lists with item numbers, sawing lists for pipes, item lists

Automatic detection of the pipe network

- Detection of drawn pipes directly in the model and analysis of the system

- Detection of all integrated components

- Consideration of technical datas integrated in the model

- Detection of drawn dimension for the optional consideration in the network calculation

- Easy mapping of foreign components for the consideration in the network calculation

Pipe network calculation incl. redimensioning

- Automatic calculation and dimensioning of all components of the gas pipe network.

- Extensive setting options for the calculation boundary conditions such as limit values for velocities, valve authorities, active pipe diameters, fixed pipe dimensions and the pipe friction resistance (R-value)

- Determination and comparison of variants of pipe materials and components incl. original manufacturer data sets with real product properties

- Calculation directly in the model incl. redimensioning

- Gas pipe network calculation according to TRGI 2018, TRGI 2008 /DVGW G600, DVGW G617, ÖVGW G11 and TRF 2012

- Calculation in every design phase directly from the model

- Calculation according to TRGI for plants with an operating pressure up to 100 mbar

- Calculation of industrial plants with operating pressures up to 5 bar

- Calculation with real product properties using data sets from leading manufacturers

- Input of substance values (methane, butane, biogas)

- Gas flow controller can be designed automatically

- Interface for valve data sets, shut-off valves, differential pressure controllers, volume flow controllers, control valves, control valves and fixed resistors

- Alternative calculations according to Zanke, Prandtl Colebrook and Prandtl-Kármán

- Design of compressed air pipe networks possible

- Visualization of results using liNear Data Coloring (e.g. dimensions, materials, velocities, pressure losses, etc.)

Hydraulic balancing of complex systems

- Hydraulic calculations with transfer of performance data from family parameters

- Calculation of multiple systems in one model

- Calculation also of networks with several control levels

- Consideration not only of the distribution networks but also of the producer

Industry components via CAD Browser

- Extensive CAD libraries with approved components of our wide range of industry partner

- More than 6 billion possible components and component combinations

- Direct placement of original manufacturer components into your model

- Multiple placing modes (place, insert, replace)

- Configurators for complex component combinations (e.g. cascade systems)

- Including technical and commercial data (e.g. article numbers and packaging units)

- Detection and consideration in the network calculations

Supported standards

LINEAR has always stood for standard-compliant calculation and design. It is both our concern to always offer the latest standards and to constantly expand the range nationally and internationally. An up-to-date overview of all supported standards can be found in our knowledge base at [LINK].

Parts list with article numbers

- Clear and comprehensible calculation results as well as complete bill of quantities

- Detailed parts lists including article numbers and material check

- Bill of quantities and parts lists in several output formats (Windows printout, Excel, text, UGS, GAEB, ASD)

Language selection for interface and printouts

We provide you with no less than seven languages, which you can use and combine as you wish, either as the interface language or the print language. In this way, it is possible to design in one language and print in another. This is a great advantage, especially for international projects, as time-consuming translations are no longer necessary. There are no additional costs for the language packages.

The following languages are currently supported:

- German

- English

- French

- Dutch

- Russian

- Turkish

- Italian

Visibility control

Visibility control with one click for:

- Building parts

- Floors

- Disciplines

- component groups (e.g. systems, insulation, etc.)

IFC interface

- IFC import of the architecture

- IFC export including all metadata

- Selection of the disciplines to be considered for the export

Storey table

- Automatic import of storeys from the architectural model

- Control of the storey in the Construction level / offset (+/-) section

- Easy Creation of storeys and work levels

FM-Tools

- Import and export of information for facility management

- Import of information from FM databases