Details on Radiator Selection/Cooling Convector Preselection

Information on the Radiator selection or Cooling convector preselection section in radiator design.

You are here:

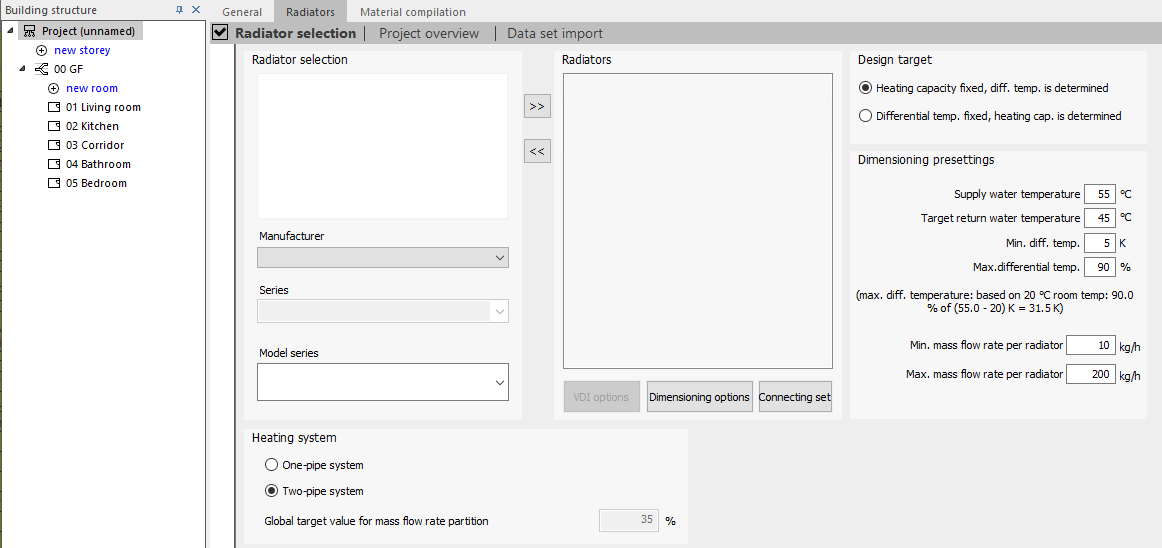

Radiator selection/Cooling convector selection

Manufacturer

Select the manufacturer of the radiator or cooling convector you would like to design. Depending on the dataset format, the menu entries in the manufacturer list are marked with <BDH> or <VDI>.

With VDI datasets, you can specify additional material and additional colors and connect locations globally or per individual radiator or cooling convector. The possible settings depend on the presettings of the selected manufacturer and on the model series. Some manufacturers also supply the appropriate connection material for certain connectors. VDI data records have to be available as LINEAR Material Management File (MMD). Depending on your license, you can import new VDI and BDH datasets at any time.

Series

Determines the series of the radiator or cooling convector you would like to design.

Model series

Determines the model series of the selected radiator or cooling convector.

Accept radiator or cooling convectors in the preselection

Press  to apply the selected model series to the preselection. Press

to apply the selected model series to the preselection. Press  to remove the preselected model series from the preselection again. The latter is only possible if the model series is not already in use. If a model series that is no longer used cannot be removed, click

to remove the preselected model series from the preselection again. The latter is only possible if the model series is not already in use. If a model series that is no longer used cannot be removed, click  one of the message buttons in the toolbar. The project is recalculated and you can then remove model series no longer used.

one of the message buttons in the toolbar. The project is recalculated and you can then remove model series no longer used.

Radiators/Cooling convectors

Radiators/Cooling convectors

List of radiators or cooling convectors model series that can be selected in the dimensioning. For each radiator or cooling convector in the preselection you can define individual settings in the VDI options, the design options and the connection sets.

VDI Options

The button opens the Product Variants and Accessories dialog, where the properties of the selected radiators or cooling convectors model series can be differentiated further according to the manufacturer's specifications.

Dimensioning option

The button opens the Radiator Dimension limits and dimensioning options to be applied dialog, where detailed dimensioning specifications can be set for the selected radiators or cooling convectors model series.

Connecting set

This button opens the Connecting Set Presettings dialog where you can select a connecting set and preset the global connection position. You can still modify the location of connection of dimensioned radiators and cooling convectors at a later stage.

Design target

Heating capacity/cooling capacity fixed, differential temperature is determined:

With fixed heating or cooling capacity, the return water temperature and mass flow are adjusted to ensure that the specified or recommended heating capacity is achieved with the radiator or cooling convector determined by the program, i.e. return water temperature and mass flow are usually lower than at maximum load.

Fixed differential temperature, heating output/cooling output is calculated

With a fixed return water temperature, the standard heat emission of the radiator or cooling convector is determined with the given boundary conditions room temperature, supply and return water temperature of the pipe run. The mass flow rate and return water temperature for the radiator and cooling convector are derived from this, i.e. the return water temperature in this case is always the pipe run return temperature.

Dimensioning presettings

The values of the supply water temperature, the return water temperature and the minimum differential temperature are coupled with each other. Please enter the values in the following order:

-

Supply water temperature

-

Return water temperature

-

Minimum differential temperature

The new values are applied to all pipe runs, unless values deviating from the default have already been set. The configuration of the pipe runs can also be adjusted again later.

Supply water temperature

Determines the global supply temperature. The global supply water temperature is used for all newly created pipe runs and existing pipe runs that have not been assigned an individual supply water temperature. You can adjust the spread for each pipe run individually. If you change the global supply temperature, the pipe run supply temperatures will also change, unless they have been individually adjusted. If the supply or return water temperature is changed, the program indicates that the mass flow rates of the radiators and cooling convectors also change and recommends a new design.

Target return water temperature

Determines the targeted return temperature. Radiators and cooling convectors are selected at dimensioning to ensure that the actual return water temperature is as close as possible to the targeted return water temperature, provided that the required output is achieved and the mass flow limits are observed. If you have selected the Differential temperature fixed, heating cap. is determined as the Design target, the calculated return water temperature of the radiator or cooling convector will be identical to the target return water temperature of the pipe run. If the return water temperature is changed, the minimum spread is suggested appropriately. If the supply or return water temperature is changed, the program indicates that the mass flow rates of the radiators and cooling convectors also change and recommends a new design.

Minimum differential temperature

Determines the minimum differential temperature in Kelvin, which should never be fallen below. The minimum differential temperature only has an effect if the radiator or cooling convector output is not sufficient and the return water temperature has to be raised above the preset return water temperature. If the target return water temperature is changed, the program suggests the minimum differential temperature accordingly.

Maximum differential temperature

Determines the maximum differential temperature in percent. The maximum differential temperature is given in percent, as it depends on the individual room temperature. The maximum differential temperature is entered and calculated as a proportion of the difference between supply temperature and room temperature. This prevents the return water temperature from falling below room temperature.

Example:

-

Maximum differential temperature: 90 %

-

Room temperature: 20 °C

-

Supply water temperature: 55 °C

Maximum differential temperature = 0,9 (55 - 20) K = 31,5 K

Minimum mass flow per radiator/cooling convector

Determines the value from which a shortage of the mass flow rate leads to an error message in the protocol.

Maximum mass flow per radiator/cooling convector

Determines the value from which an exceeding of the mass flow rate leads to an error message in the protocol.

Heating system

One-pipe-system/Two-pipe-system

If you are using a one-pipe system, you can enter the reference value for the mass flow rate partition globally. The mass flow distribution is controlled by one-pipe radiator valve, which are used instead of lockshield valves on each radiator or cooling convector. The hydraulic balancing then takes place only via regulating valves. No thermostatic valves are required for one-pipe systems.

Global reference value for mass flow distribution

The intended target value for mass flow splitting is initially applied to all new pipe runs. The calculated value can deviate from the target value, for example, due to the requirements of the individual radiators or cooling convectors in terms of performance. The mass flow partition can be adjusted in the individual one-pipe runs. The default value suggested is 35% mass flow splitting. This 35% of the mass flow is fed directly to the radiator or cooling convector. The remaining 65% of the mass flow bypasses the radiator or cooling convector and supplies the next radiator within the series circuit.