Social awareness is growing constantly for the kind of sustainable development that stands for responsible use of finite resources, fair global trade, and justice toward future generations. On the other side of the coin there is the construction industry, where there is a substantial consumption of resources. Roughly half of the global volume of waste material can be attributed to the construction industry. Emissions are rising, the scarcity of resources is evident in the increased price of construction materials, and in the context of the current climate debate the difficulties in the disposal of special waste mean growing calls for sustainable building. A solution to this problem is supplied by the Cradle to Cradle® concept. The principle was conceived back in 2002 by the chemist Michael Braungart and the architect William McDonough. The design concept offers a holistic approach and requires that products are designed with the intention of feeding them back into the material cycle again at a later date. This ensures that the materials are compatible with recycling or composting and remain part of the cycle as important resources. Here BIM plays a key role in the implementation of the concept in construction and supports the realization of the sustainable building vision.

PROPER “CIRCULAR ECONOMY”

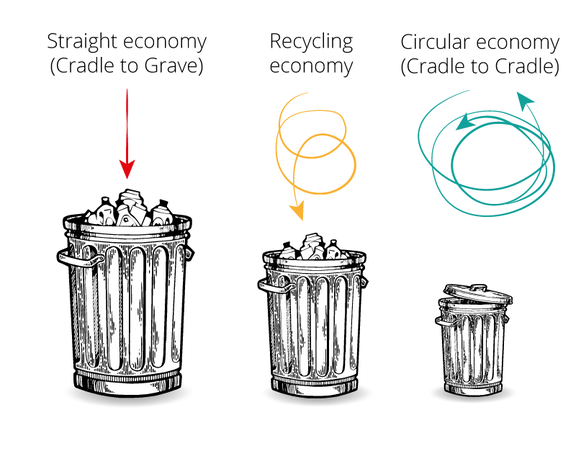

What distinguishes the Cradle to Cradle® concept (abbreviated here as C2C) and an associated circular economy from common recycling methods is the fact that in the recycling process valuable materials are lost or the original quality suffers in the handling process. The reason for that is that during industrial production the materials contaminate one another and make it difficult to separate the materials again in the recycling or downcycling process. Consequently, valuable raw materials end up in dumps and have negative or even toxic effects on the environment. That is why the C2C concept necessitates a rethinking process. A linear way of thinking (cradle to grave), which is largely practiced in today’s economy, must give way to a recyclable way of thinking (see Figure 1).

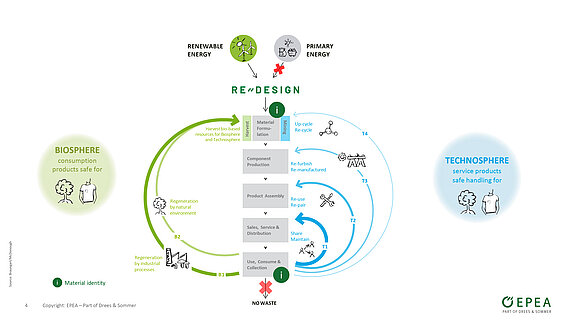

The C2C concept is based on three principles and forms the framework for the development of innovative design. The first principle states: “waste is food”. Accordingly, only homogeneous and reversible compounds and materials may be put to use in the material cycle, so that the materials can be returned after their use phase to the recycling system. The second principle stipulates the use of renewable energies. This is because fossil fuels are finite and produce emissions. Instead, sustainable energy sources such as the sun, water, wind and earth (geothermal) are to be the focus. The final crucial point is biodiversity. C2C is to be understood as a holistic approach, which doesn’t attempt to simplify complex issues or seek one-dimensional solutions. This also includes biomimicry (aka bionics) for example, which mimics existing and natural concepts in nature. Dirt-repellent coatings are based on the lotus effect. Another strategy for biodiversity is utilized by a heating plant in Bremen, for example: The excess CO2 is used by algae and is indispensable for these organisms to live. Afterwards, the algae are processed into feed for aquacultures or raw material for industrial use. This is a spectacular example of how there are no limits to innovation.

„That is why a genuine circular economy according to the C2C Principle doesn't start with waste and the recycling process, rather it starts with proper product design in building planning.“

Peter Mösle – CEO of EPEA GmbH

Another distinctive feature is the aspect of eco-effectiveness. For the C2C school of thought it is important to take advantage of creative innovation. Being merely “less bad” is not beneficial for the environment in the long term. The vision involves not only reducing the footprint, but leaving behind a positive footprint.

BUILDING WITH A POSITIVE FOOTPRINT

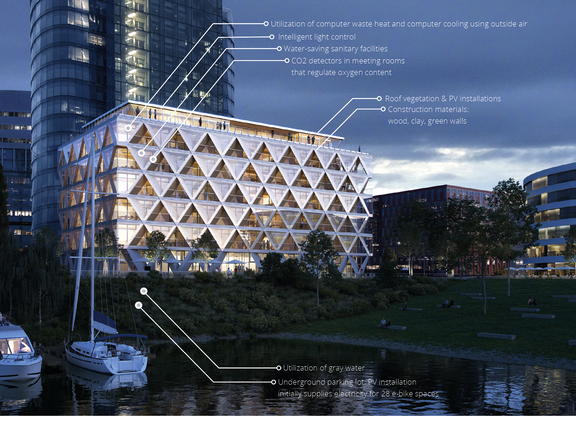

How successful this can be is demonstrated by the “The Cradle” flagship project, designed by HPP Architects, in the Medienhafen in Düsseldorf (see Figure 3), the construction of which has begun already (in spring of 2020) on behalf of the innovation-driven project developer Interboden. In line with its name, the wood-hybrid office building is aimed at having a positive effect on the environment and human beings. The building is made mainly out of wood – with the exception of the basement, ground floor and core structure – which is especially visible in the rhombus-shaped facade. Because of the depth of the construction, through its varying dimensions the wood pattern produces shadows – dependent on geographic direction – in the form of a grid, which is especially beneficial in summertime. Moreover, the raw material has the ability to bind CO2 in the air, so it contributes to an improvement of air quality indoors.

„Imagine a building that is like a tree: It purifies water and air, generates oxygen, and yields earth and nutrients.“

Prof. Michael Braungart, PhD, developer of the C2C design concept and President of EPEA

On top of that many other materials are used, the constituents of which were tested in terms of their material health, recyclability, and separability, taking into account the transport routes and installation of these building components. All materials on the EPEA banned materials list were deliberately avoided: for example, toxic raw materials such as materials containing PVC may not be used. Neither are adhesives or irreversible material mixtures used. Instead, installations are mounted using screw connections or anchors, to ensure they can be dismantled at a later date. “The Cradle” can be largely dismantled when it becomes unusable. Any usable residues can then be recycled by feeding them back into the technosphere or biosphere, to be used loss-free, as far as possible, for construction projects at a later date.

FURTHER C2C MEASURES IN "THE CRADLE"

- Where possible MEP elements were introduced as modular components (e.g. the entire building ventilation system).

- Fastenings were installed using a C2C-certified system from Würth.

- Generic MEP elements are mounted in a visible and ordered manner and can be easily replaced during the utilization phase.

- Because of the visible installation without suspended ceilings it is more flexible for conversions such as converting individual offices to open-plan offices without major changes to the MEP elements.

- Service openings in the underground garage ceiling allow replacements to the building ventilation system during the utilization phase.

BIM SUPPORTS IMPLEMENTATION

The project received a special award from the Heinze ArchitekTOUR congress as best BIM project. Because of their complexity, digitization of the work processes is particularly vital in C2C projects. This is exactly where BIM is an essential tool for future-oriented construction projects. The advantage is also collaboration on a single platform: Thanks to IFC standards, each project participant receives access to the latest building model. So, for the first time, the discipline of the C2C concept and BIM were successfully combined in the course of the project. BIM helps to understand the complexity, increases acceptance of the concept, and ease of implementation is improved considerably.

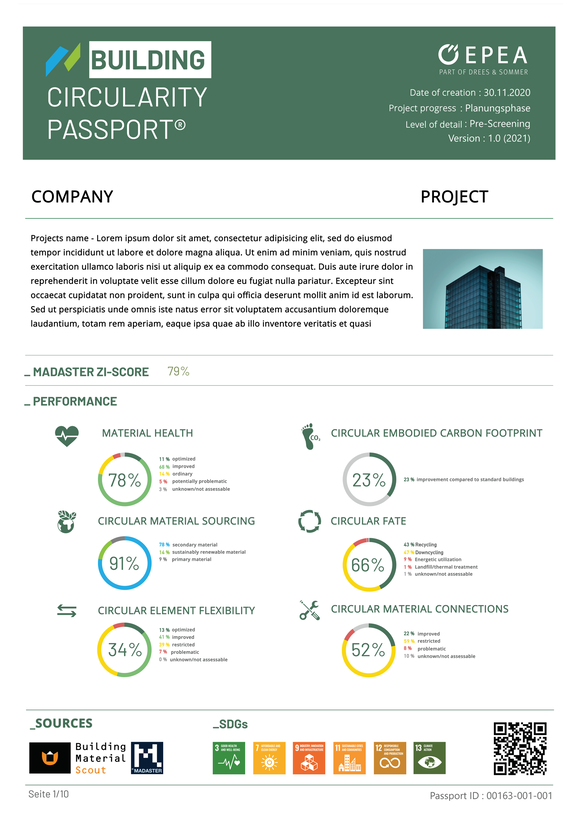

BUILDING MATERIAL PASSPORT DIRECTLY FROM THE BIM MODEL

Principally, by depicting all relevant data directly in the BIM model, it was possible to catalog electronically in the building material passport (building circularity passport) the information related to the envisaged materials, and to organize it in relation to the C2C criteria in terms of composition and suitability. This resource passport was developed by EPEA GmbH and Drees & Sommer, and proves to be particularly helpful for the planning and documentation of the project (Fig. 4). Requirements become clearer for everyone involved in the project. With a digital interface, all changes to the building are recorded and updated automatically. So the materials used can be exactly traced, and even years after completion of the building, information on what was installed when and in which position is still comprehensible.

C2C RAISES THE MARKET VALUE OF A BUILDING

According to calculations by Drees & Sommer, C2C buildings can increase in value by up to 10% compared to conventional buildings. After successful implementation according to the C2C principle, the building can be understood as a resource depot, which can be drawn upon again after use. Scarce resources can then be dismantled from the building in unchanged quality and reused. This especially benefits posterity in the long term. Added to that, the building material passport mentioned also promotes awareness for energy and resource consumption throughout the entire life cycle of a building project, and fosters a holistic understanding. The building owner can naturally also use this for publicity purposes, to attract attention to the building.

C2C RAISES THE MARKET VALUE OF A BUILDING

According to calculations by Drees & Sommer, C2C buildings can increase in value by up to 10% compared to conventional buildings. After successful implementation according to the C2C principle, the building can be understood as a resource depot, which can be drawn upon again after use. Scarce resources can then be dismantled from the building in unchanged quality and reused. This especially benefits posterity in the long term. Added to that, the building material passport mentioned also promotes awareness for energy and resource consumption throughout the entire life cycle of a building project, and fosters a holistic understanding. The building owner can naturally also use this for publicity purposes, to attract attention to the building.

SIGNIFICANCE FOR THE MEP DESIGN

The structure and the materials used are naturally crucial for successful implementation of the C2C principle. Constituents such as concrete, bricks, sand-lime brick and other mineral materials alone account for 85% of the material weight used in the inventory. However, to achieve a really positive footprint for the entire building, it is essential that the building construction and the MEP elements be planned together according to the C2C principle.

Since MEP elements usually have a considerably shorter lifespan and are replaced or expanded during the service life of a building due to technical improvements or changes to expectations on comfort and aesthetics, they are highly relevant for the recyclability of a building project. Special attention must be paid to separability of the systems. If the separability of the MEP elements from the rest of the building structure is well thought through, it can simplify the utilization of building materials for recycling or other purposes. Easy accessibility for purposes of replacing building components simultaneously leads to reductions in maintenance costs. The use of pre-wall installations is a fitting example here. These factors can and should be taken into account already during planning. Another point of application is the planning of certain reserves in vertical shafts and pipeline corridors, to be able to react flexibly to future requirements. It is natural that conflicts of interest can arise here among the individual parties involved. For example, consistent system separation can conflict with the creative freedom of the architect or the aesthetic expectations of the building owner. Here, in particular, interdisciplinary cooperation and the involvement of all participants in a BIM process is highly advantageous, so that compromises can be reached and joint decisions made directly in the model. Of course, everyone involved should agree in principle that aspects such as material purity, reusability, easy servicing and a dismantling concept are given higher priority in all considerations.

„Nothing is thrown away here.“

Johannes Wiesinger, Drees & Sommer Senior Projectpartner and MEP-Expert

Even manufacturers from the MEP area are increasingly recognizing the potential and sense of the approach, and adapting their products and services accordingly. Würth, for example, developed the first C2C-certified quick-fit system in the world, called “Varifix”. In connection with this the option of taking complete responsibility for construction site logistics involving delivery and reverse logistics for dismantling of the rails and fastening systems is offered. This way, the materials can be dismantled and processed again industrially. Reusability can also spark the creation of new business models. In this context, Würth is testing a leasing concept which involves consigning the components to the building owner for the period of use. For the manufacturer this allows an overview of the complete value chain.

Another example is LINEAR’s industry partner Rehau, which received a Cradle to Cradle certification for its Awadukt PP SN 10 and Awadukt HPP SN 16 sewer pipe systems (see Fig. 5). More innovations, new products and business models are to be expected in this area in future, which will facilitate recyclable use of construction materials. The vision behind C2C turns buildings into key players in a built-up environment. It involves buildings that clean the air and water, are positively energy-efficient, increase biodiversity, make a positive contribution to the social surroundings, and promote the health of their users. The parameters formulated make clear how important this is for MEP. It is about ensuring an efficient supply of renewable energy to the building and optimizing the use of water and air, to facilitate self-sufficient use. It can produce intelligent systems that give more than they take, and also make a contribution above and beyond the mere use of a building. So, inventiveness and innovative spirit of the engineers are called for here, which will provide a new opportunity for the industry to shift the focus to the importance of planning and implementation of MEP design.

MODULAR PREFABRICATION FOR MORE EFFICIENCY AND PLANNING SECURITY

Another C2C pilot project is currently underway in Stuttgart: The new DRESO office building is being developed with the help of modular building equipment. The MEP elements for the energy-plus building were designed primarily taking C2C design principles into account.

At a manufacturing location the individual components are industrially prefabricated and subsequently installed at the construction site. Since production on location at many construction sites is difficult because of weather conditions, the system offers advantages through time and cost savings. Moreover, improved planning beforehand is possible, as well as volume production of the modules. To guarantee compact construction of the components, for modular design it is necessary for the trades to merge with one another. In the process, preplanning with BIM is essential, to keep on top of information about dimensions, technical properties and raw materials, and allow it to be integrated into the building model.

Ultimately, implementation using C2C in combination with technical tools is a potential means of confronting the approaching challenges. Naturally, this can only succeed if everyone involved takes a sustainable approach. Thanks to BIM, the level of complexity that a project reaches because of new requirements is structurally evident for everyone involved. It is easier to communicate suggestions for optimization in the building model within the team. As such, BIM acts as an interface for everyone involved in the project, and serves to provide a comprehensive overview. C2C is a promising approach that factors in the beginning and end of a product cycle, addressing the resource and climate problem this way all at once. It will be interesting to observe whether the principle can establish itself widely in the market, and thus have a real impact.