![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/f/csm_Vogtareuth_01_9ac8e0dc90.jpg)

OLDER BUILDINGS, ANALOG ICE

As is often the case in such situations, the successive expansions produced a disparate collection of technical equipment in the buildings, which increasingly failed to satisfy modern energy standards. Heat was generated with three boilers from the years 1984 and 1991, with a total power of 3 000 kW. The primary energy source for heat generation was butane, because back when construction started there was no natural gas supply in the region. In peak load periods, two trucks a week delivered the liquid gas, and the overall conditions with underground explosion-proof tanks was complicated and hazardous.

For the hot water supply there were three systems with water heaters set up in series, and the cooling was supplied by two circuits, each with a compression refrigerating machine with 460 or 310 kW power. The IC technology was still analog, and most of it had been built in the 1980s. The closed-loop control system was inefficient and the boiler unit was regulated independently of the outside temperature.

Because of the situation at the time, the clinic decided to do extensive renovations in the areas of heating, cooling and potable water, based on an energy concept. At the time, two other new constructions were already being planned, which in the meantime have been completed: the children’s ward with 50 treatment units, which was inaugurated in 2014, and the new state-of-the-art surgery center with intensive care station, which entered operation in autumn of 2015. When the energy concept was prepared it already took the heat supply for the planned new constructions into account. The areas of hot water and cooling could be set aside, because the new buildings are equipped with water heating systems using a continuous flow principle, and the new cooling station in the surgery center supplies cooling for the entire clinic. The room ventilation technology in the existing buildings was also not part of the energy concept, because most of the more energy-intensive areas were moved to the new construction built later.

EXTENSIVE RENOVATIONS

The renovation measures envisaged in the concept were completed by the end of 2012. Essentially the measures affect the generation of heating and cooling, distribution systems, the hot water supply, and IC technology. The primary energy for heat generation was converted to natural gas, and an 8.8 km long pipeline was laid specially for the clinic to connect to the natural gas grid. The old boilers were replaced with two combined heat and power units (CHP) and a new boiler unit. The CHPs cover the clinic’s base thermal load. Two power units supply 140 kW electrical and 207 kW thermal output each. Added to that are two low temperature boilers, each with 2 200 kW output and 200 kW waste-gas heat exchangers. When needed, the boilers can handle the entire heat load of the clinic, which means that a heating supply is fully guaranteed even if the CHPs are down. For safe operation the heat generators (boilers as well as CHPs) are hydraulically decoupled from one another. For this a Zortström distribution system is used, which decouples both generators as well as consumers. Layer separating plates allow optimal integration of the individual consumers, and a higher differential temperature between supply and return water pipes.

For the cooling supply the two existing systems, which had been separate until then, were joined together hydraulically, to be able to centrally supply all cold consumers in the existing buildings in future through the new cooling system in the surgery center. But because one of the two existing cooling generators didn’t offer enough operational reliability for the interim period, it was replaced as part of the renovation measures. Moreover, the existing water heaters with a total of 25 500 liters capacity were converted to flow generation systems, with heat exchangers. The heat is not retained any more through hot potable water storage, but hygienically safe through heating buffer storage, upstream from the plant equipment.

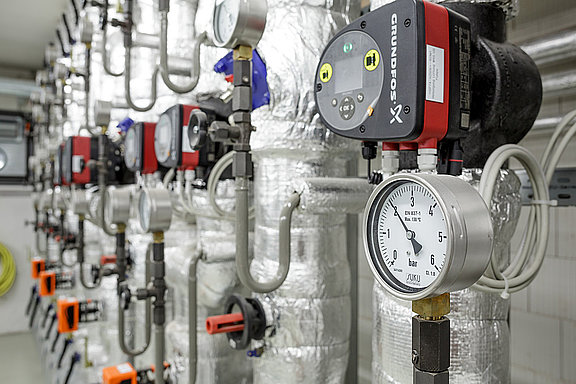

HIGH-EFFICIENCY PUMPS FROM GRUNDFOS

An important element of the energy renovations was a hydraulic balancing of the entire clinic complex, and the replacement of older circulating pumps. The entire heating system was recalculated, to ensure optimum design of the energy flows. To implement this, some 7 500 radiators were adjusted in the existing buildings with new pre-settings. With the optimization of heat distribution, it was possible to save around 5% of the heat energy.

The replacement of the circulating pumps resulted in considerable savings in electric power. Many of the existing pumps didn’t have any control systems and had power consumption ratings of up to 1 500 watt. In the course of the renovation work more than 40 existing pumps in the heat distribution system were replaced by electronically controlled high-efficiency pumps from Grundfos. In addition to two type TPE 100-70 electronically regulated inline pumps, particular use was also made of models of the Magna3 series. This versatile wet-runner series can satisfy an array of different needs. For the renovations in Vogtareuth a total of 47 Magna and Magna3 pumps were installed in the installation sizes of 25-60 to 65-120F. Most of them replaced inefficient pumps already in place, and in some cases (such as the supply lines of the new CHP units) they were new installations.

In addition to the heat generation and distribution systems, the analog IC technology was also replaced. The systems are now controlled and monitored digitally through a building services engineering system. A new fault monitoring system ensures that fault alarms go directly to the technician on duty and can be promptly rectified.

MORE SELF-SUFFICIENCY, CONSIDERABLE SAVINGS

The people in charge view the results of the renovations positively. “The modifications have brought us clear savings, a considerably higher share in supplying our own energy, and more operational reliability,” says Peter Esterer from building management VT of Schön Klinik Verwaltung GmbH. “The bottom line is, in the first year we saved around 250 000 euros. Through additional optimizations in the operation of the CHPs we were able to reduce the amount of power obtained from the energy supplier even more, and compared to the situation before the renovations we now save roughly 300 000 euros per year. On top of that, we have reduced CO2 emissions by 628 tons per year.”

The drastically reduced power consumption of the pumps is especially remarkable. Added together, prior to the renovations, the energy required by the 46 existing pumps in the central heating plant and sub-centers was 148 910 kWh per year. The new high-efficiency pumps are considerably more efficient and require 44 245 kWh energy per year – a savings of 70% (even though four additional pumps are necessary because of the CHP and the flue gas heat exchanger). At a rate of around 14 cents per kilowatt hour, alone the use of the high-efficiency pumps saves more than 14 000 euros per year in operating costs.

NEW SURGERY BUILDING WITH THE SAME TECHNOLOGY

Because of the positive outcome of the renovations, the same pump technology was chosen for the new surgery center building completed in autumn of 2015. In the replacement of the heat generation systems the heating requirements of the new building, whose effective area is roughly the same size as the existing facility, were already taken into account. For the surgery center, all that was necessary was to create a sub-distribution system, which was to supply the AHU devices, hot water heating system and the static heating areas. In the new cooling station, too, which now supplies the entire clinic including operating rooms, intensive care station, sterile goods supply, and IT, the operator depends on pumping technology from Grundfos. A total of 12 TPE series inline pumps and 24 Magna3 wet-runner pumps in installation sizes between 25-80 and 65-150F are installed in the surgery center. All pumps are speed-controlled, and some are controlled centrally over a bus interface through the building services engineering system. The clinic has consistently chosen efficient operation here, too.

“A heterogeneous collection of buildings that has undergone several new expansions is a genuine challenge for the building engineering,“ concludes Peter Esterer. “With our energy concept, the renovations, and the integration of the new constructions we succeeded in bringing the building services engineering in Vogtareuth uniformly up to date. And it pays for itself in terms of operating costs and reliable operation.”

The positive outcome is also setting an example for others within the clinic group. Already in planning is a new extension at the Schoen Clinic München Harlaching, a clinic specializing in orthopedics. Construction began in the second half of 2015. Again here, the clinic has chosen state-of-the-art pump technology from Grundfos.

GRUNDFOS PUMP DATA AND CAD LIBRARY

Grundfos product data along with pump and control characteristics are available for the pipe network calculation program from LINEAR. The Grundfos CAD library offers optimum support for planners, with 3D models and 2 views for the design engineering. With the Grundfos CAD browser, users who don’t yet use any LINEAR software gain a powerful tool for AutoCAD. The data sets and CAD libraries are free for all users and can be downloaded vie the LINEAR Installation Center.

www.schoen-kliniken.de – www.grundfos.de