![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/e/csm_UG_Print_12_b1bc7bc53c.jpg)

The Russian company, JSC “VNII Galurgii” has specialised in the complex planning of systems for the potash industry for over 85 years. The institute functions as a general planner at sites belonging to PJSC Uralkali, one of the world’s leading potassium producers. Uralkali produces a significant proportion of the global potassium chloride volume and controls the entire production chain – from the extraction of potash ore to the supply of finished products to consumers across the globe.

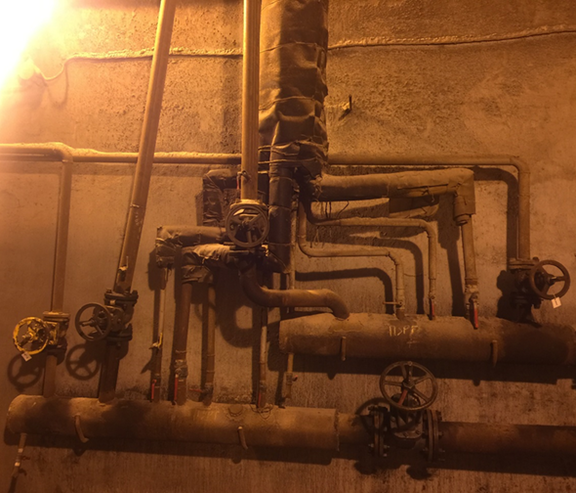

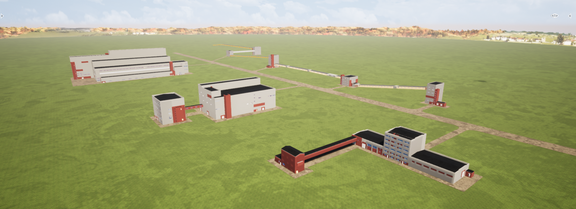

JSC “VNII Galurgii” began the BIM-compliant planning of the implementation years ago. As a result, experience in the development of information models was gained, both for new-builds and for existing property and facilities requiring a refit. The implementation of BIM projects takes place in a single information environment. In 2019, the company began transferring all existing buildings, including existing heating systems, to digital models (fig. 1).

This formed the basis for the development of optimisation measures to increase efficiency. For the realisation of the project, it was decided to use LINEAR software, as it integrates seamlessly with the Autodesk Revit platform that was already in use and also has a certification for its compliance with Russian standards.

During the first phase of the pilot project, the specialists at the institute investigated the heating and internal heat supply systems of five buildings that functioned as potash ore transshipment nodes. The project covered a total area of more than 2,000 m2 plus five inclined transport galleries with a total length of more than 1 km.

The first step in the implementation process was the creation of models of the buildings and structures. The basis for this was architects’ drawings, building permits and new plans, alongside the thermal characteristics of building shells which were the result of measurements. Using Autodesk Revit, the building shells were created and information on the thermal conductivity of their components collected for further calculation in the building model.

Then, in the second step, the heat losses from buildings and structures to the environment and the resulting heat load were calculated. This calculation was done using LINEAR Building software in accordance with the requirements of the Russian standard SP 60.13330.2016. The functions of LINEAR Building allow the preparation of the 3D building model for analysis and then the creation of a calculation model. This model was used as the basis for the thermal load calculations, which were made using LINEAR Building Heating.

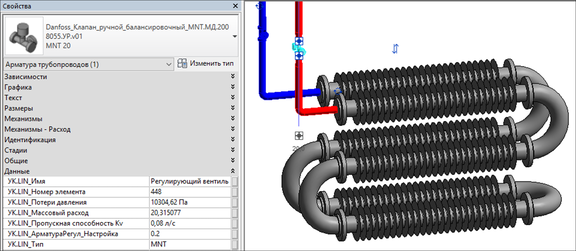

The subsequent third step consisted of modelling heating systems and the internal heat supply in the Revit model. Information on the thermal output and pressure loss were transferred from technical data sheets to the components of the model.

The main task in the development of systems is of course to achieve stable thermal and hydraulic operating states through the correct distribution of the heating medium in accordance with the determined thermal loads. In this fourth step, the hydraulic calculations made using LINEAR Analysis Heating helped to make the right decisions. In the context of the calculation for the heat supply systems, the optimum locations for equaliser valves, their size, design parameters and settings were determined and recommendations were made regarding the alteration of the piping routes in existing facilities to increase their effectiveness. Finally, the set values of all regulating valves were automatically determined and output.

Thanks to the visual representation of the source data and calculation results, and the direct communication of the calculation by the LINEAR Software using the 3D model of the building, all existing problems in the various heating systems could be evaluated exactly.

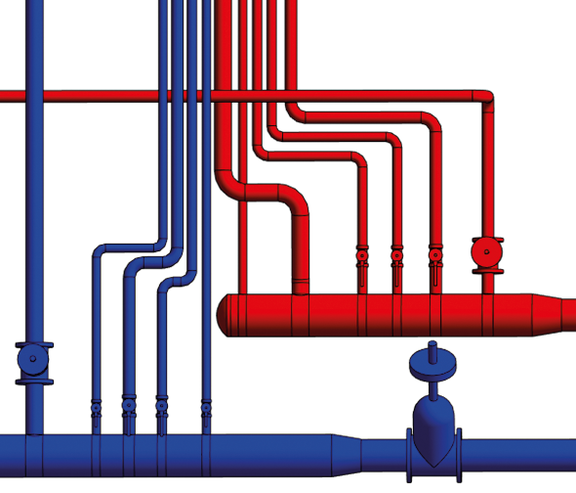

To ensure a correct calculation, systems must be modelled correctly. One of the problems determined during operations was that heaters (registers) with small loads connected in a single-pipe circuit could not be equalised by valves with neighbouring branches. In these cases, the pipework was changed from single- to double-pipe systems (fig. 2).

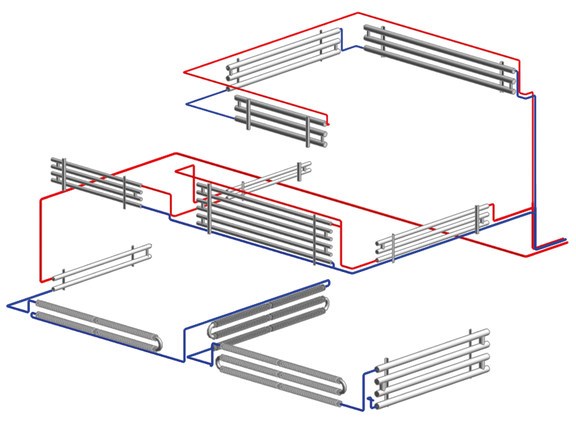

In close cooperation with the LINEAR team, inexactitudes in the modelling of construction systems were eliminated and important nuances in the creation of Autodesk Revit families explained (fig. 3). LINEAR also profited from the cooperation and was able to improve the software according to the requirements of the Russian market, providing these improvements promptly via an update.

The fifth and final stage was the cost evaluation for the implementation of the planned measures (disassembly and installation of pipes and valves). The estimates were made using information models with the Russian software Gektor 5D Smeta.

The results of the work were presented to the customer using Autodesk Navisworks. To this end, various 3D views and sections were created, in which relevant elements in the model could be selected to display their characteristics. This made the traditional exchange of paper work results between client and contractor unnecessary, bringing the client into a shared data environment. This allowed the engineering services to be optimised significantly.

The information models of buildings and structures with heating networks do not lose their validity after the calculation, but can continue to serve as a source of information. The client’s employees are provided with information on the location of each device, its technical parameters and further data for use in Facility Management. In the future, the plan is to add maintenance data to these models so that they can be used as an operational database when carrying out work. After the successful pilot phase, work on further trades is planned. Ventilation, water systems and electricity will also be digitally recorded and optimised. Over time, a “digital twin” will be created for each of the client’s objects.

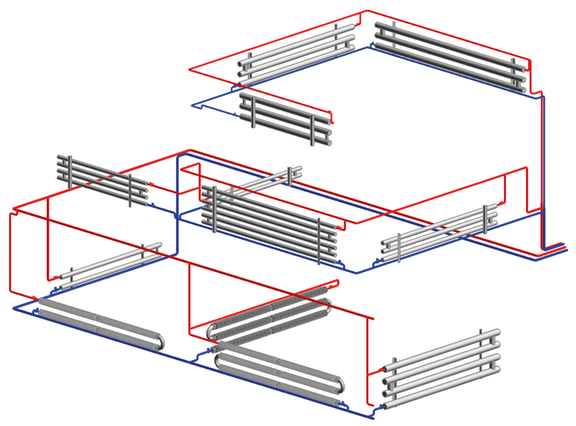

The successful completion of the first phase of the pilot project allowed us to continue our tried-and-tested methodology in the second phase too. In this phase, five buildings were also digitally recorded and their heat supply systems optimised (fig. 4), but this time with a total area more than ten times greater, at 25,000 m2. Following the overwhelmingly positive results from the first two phases of the pilot project, the client decided to create digital models of all the buildings and structures in its enrichment facilities.

“I would like to express my thanks to the team from LINEAR. The technical support team helped us immediately with any problems that arose and also with the solution of non-standard tasks. The fact that, at LINEAR, development and technical support work together so closely led to rapid results even in the most difficult cases. Their authorised partner in Russia, NIP Informatica, also supported us with advice and practical help.”

Aleksey N. Balyshev,

Head of Building Information Modeling department

Authors

Anastasiia Bakhareva

Engineer, BIM-Coordinator,

Building Information Modeling department

Elena Malinina

Engineer, heating and ventilation sector

Aleksey N. Balyshev

Head of Building Information Modeling department

Founded in 1931 on the basis of the Salt Laboratory of the USSR Academy of Sciences, the Institute conducts a wide range of researches for studying geology, hydrogeology, geomechanics of salt and potash deposits: In Belarus, Ukraine, the Urals, Siberia and the Central Asian republics, underground technologies for highly mechanized extraction of potash ores and underground leaching of potash and salt deposits are being developed.

Currently, VNII Galurgia JSC has 14 research laboratories and 24 design departments with more than 500 employees.