![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/7/b/csm_webseite_PGMM_aae077881e.png)

He was one of the greats among physicists; Already in 1927, on the sameplot where the new research building is being constructed, Walther Meißner commissioned a low-temperature lab . At the time, all of it belonged to the predecessor of the PTB, the Physikalisch-Technischen Reichsanstalt (PTR). There, Meißner made groundbreaking discoveries: He discovered new super-conductive elements and researched their behavior. Even though the laboratory was destroyed in the 2nd World War, the foundation had been laid for a focus on research in which PTB is a world leader today: Since the 1980s the development and manufacture of highly sensitive superconducting quantum interference devices (SQUIDs) is a major topic here. These SQUIDs serve as sensors for measuring unimaginably small magnetic fields, such as those produced by the human heart or brain. With these, as well as their devices and magnetically shielded rooms, some of which are unique in the world, the PTB is an international leader in the development of new diagnostic methods for heart and brain activity, as well as research into basic physical principles, such as the study of the properties of magnetic nanoparticles. But the new Walther Meißner building also offers unsurpassed conditions in its surroundings for other areas of research: such as the cryostat systems for thermometry, which are likewise of international excellence. With them the PTB can guarantee the German thermometer industry, primarily consisting of medium-sized companies, calibration of their products across a very large temperature range, all from one source.

Moreover, in the building the PTB will supply the “new” Kelvin: Since the 20th of May 2020 the SI base unit for temperature, the Kelvin, isn’t defined by the triple point of water any more, but by a constant of nature – the Boltzmann constant. In the new building the PTB will effectively “create” the “new” Kelvin – or to put it more scientifically: they will directly describe it. To do this a so-called noise thermometer will be used – a quantum-supported temperature standard. With this the PTB measures the Kelvin by measuring a voltage, traceable directly to a Josephson standard. This is how the PTB can continue also to expand its leading position in the field of primary thermometry.

The development of innovative precision electronics for metrological applications will also be continued. In the laboratories, too, research on optical single-photon radiometry will be done as part of PTB’s new quantum technology center.

COOPERATION IN AN OPEN SYSTEM

The intensive cooperation of everyone involved in the project in the cross-trade coordination model was exciting pioneer work. The head of the overall project had no experience

as to the effect his structural specifications would have on the data transfer in the project communication system. Proven 2D-capable structures could not be simply transfered; even the usual identification by floor doesn’t work in IFC files, because they always include the entire model across all levels.

Even if every designer already had model experience personally, work in the big open BIM with the exchange of information among involved designers first had to establish itself:

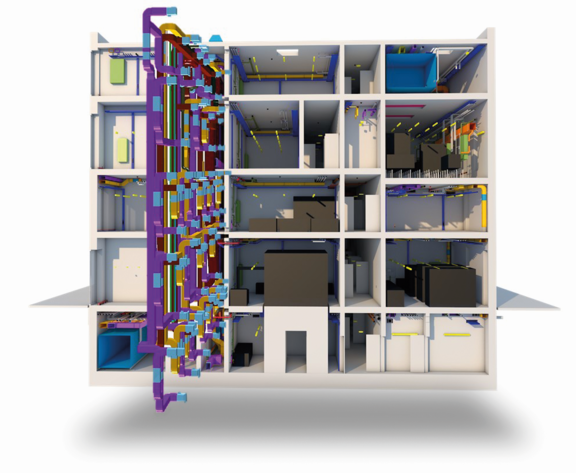

The design work for the entire building was done according to the BIM method:

- Architects

- Structural engineers

- MEP design (PGMM)

- Laboratory design (PGMM)

PGMM worked with the LINEAR software product. The choice for company-wide introduction was made using a requirement matrix. Inter alia, the following criteria were used to test and evaluate various software tools:

- 3D and BIM-capability

- Software development to be expected

- Calculation tool for all mechanical trades

- Open interfaces

POTENTIAL IN THE MODEL-BASED DESIGN PROCESS

The initial thoughts on the optimum positioning of the main shafts and the equipment rooms were done in the project with 2D floor plan depictions, into which system symbols were inserted. In the clean room section on the second floor, which is a defining feature of the building, to avoid particle contamination in the semiconductor processing areas, laminar flow units were envisaged in recirculating air operation. With the choice of an energy and maintenance-efficient air supply system via pressure plenum from the technical area situated above, it was virtually possible to confirm the southern floor plan zoning from the competition design.

To supply the middle-inner laboratory zone, an additional walk-in shaft became necessary on all floors across the entire length of the rear laboratory walls. For regular maintenance of the more than 80 fire dampers there, the prescribed maintenance walkways were to be kept free as structural clearances.

This large central shaft made it necessary to widen the entire building by more than 3m. Already in pre-planning it was possible to take advantage of model-based design with BIM here to determine for development the required cubage of the shaft with all its crossing lines, which in the past, with conventional collision planning, was often only found out too late. “Build it twice” is what this construction work simulated with BIM is called, through which risk at the construction site is reduced.

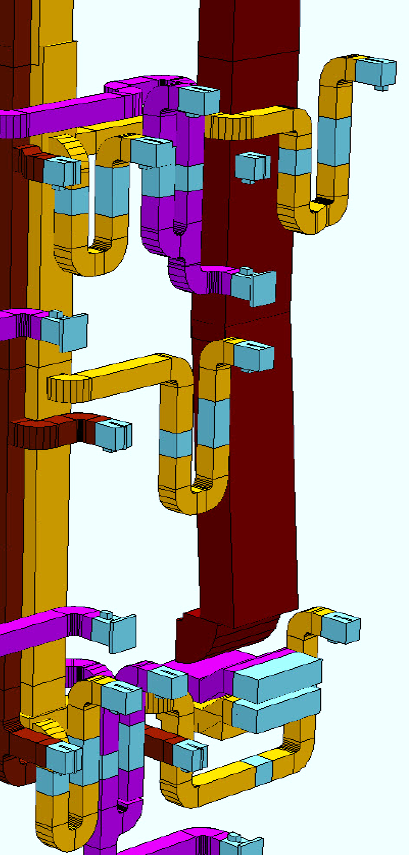

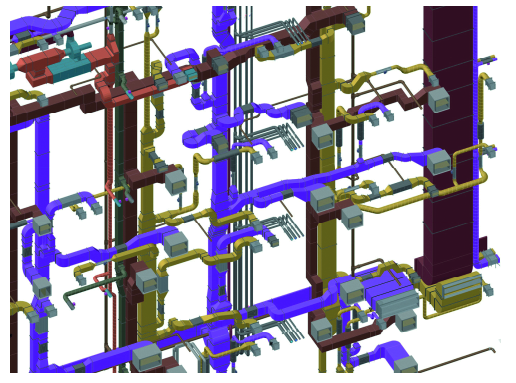

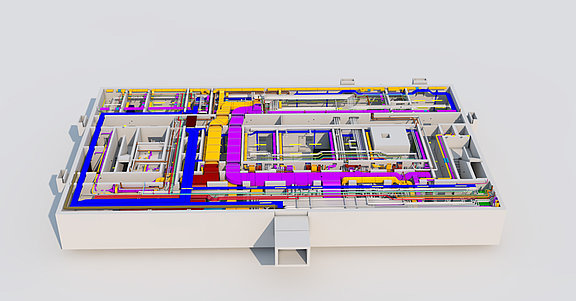

Figure 2 depicts the design engineering for the ventilation ducts with the rough cubage and functional elements such as flaps and sound absorbers. With the 3D graphic, the depiction doesn’t suggest the sketchy impression of an approximate design any more. It includes the elements required to make a decision, based on which the project management asked for an increase of more than 6000 m³ to the cubic content (gross cubic space), even before the implementation costs were verified. The model-based implementation design of this section in the ventilation shaft (Figure 3) demonstrates impressively how the level of detail developed up to work phase 5.

Before completion of the implementation design for the initial trades, the planning stage reached was presented to the future users in a joint 3D workshop.

The consistent model quality permitted the conducting of various simulations by involved specialist planners through the IFC interface, even though some of these, such as structural dynamics experts and building physicists, were not involved in the data integration for the overall model. The high shock requirements on the structural dynamics, particularly for the clean room level, resulted in specific threshold definitions for the rigidity and inherent frequency of the construction. This could only be achieved using an in-situ concrete construction method with a high reinforcement percentage of the 30 cm thick concrete walls, with rigid slot and opening design. With the help of the 3D collision check, the positions of the openings could be coordinated early on in the route planning. Compared to the conventional planning process, changes to work could be made in the early phases.

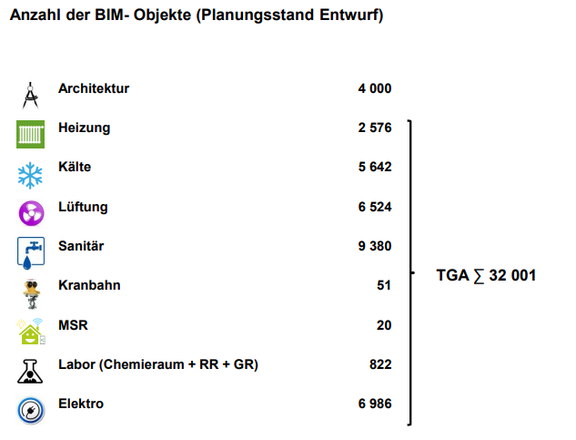

PLAYERS IN THE BIM

Based on the number of BIM objects used in planning as well as the data size of the respective technical model, it became clear that the MEP designers in the BIM application could be counted as the main players. Figure 4 shows an analysis of the object data.

For the more intensive interdisciplinary work, the software providers developed versatile tools. For model checking, communication and evaluation there are a wide range of protocol systems. And to approximate the wishful thinking of an idealized fully-automated collision check system, convenient viewer functions are already available, which locate collisions in efficiently prepared graphics, and even depict the incidence of the collision type in the building in a spatially clear manner in a synopsis consisting of superimposed isometric floor plans.

It is only human nature that exchanging information through input screens involves a risk of the planning team losing the personal touch, that the digital approach to communication is too one-sided, and that identification with the joint effort must be maintained in other ways.

MODEL VISION FOR RESEARCH WORK

Through the federal BIM pilot project “Construction of the new Walther Meißner building” for the National Metrology Institute (PTB) of Germany in Berlin we got digitized planning processes in the big open BIM (Level 2) off the ground with building planners, structural engineers and specialist planners in a building of modest cubage but of highly specialized scientific use.

From the draft right to the implementation design of this research building, through a model-based approach it was possible to react considerably more precisely to the requirements of the research work. This added value, derived from the BIM process, will hopefully remain evident in the daily metrological work of the PTB.

Since the founding of Planungsgruppe M+M AG in 1970 we have developed steadily with consistently good growth and specialization and become a company that is active in many regions.

Our employees are supply engineers, electrical engineers, environmental engineers, medical engineers, and hygiene technology experts as well as chemists, physicists, biologists and economists. In interdisciplinary planning groups we develop technical solutions for infrastructure and furnishings for new buildings and building modifications, renovations and for ongoing operation.

Actively taking advantage of the latest technological developments, implementing practical solutions, the willingness to take innovative approaches, as well as our knowledge of customer processes and goals are the basis of our development and our success.

As a corporation, our company structure facilitates our long-term development. All ownership interests are in the hands of our top management. As such, our planning group is completely independent of other companies.