In the last issue of LINEAR AKTUELL, the article "Sustainable construction with Cradle to Cradle" (short: C2C) dealt with the topic of how buildings and the materials used can be designed in advance to be recyclable in accordance with the C2C concept, so that at best they can be seamlessly returned to the cycle of re-usability after their utilization phase. In line with the guiding principle of "storing" raw materials for future use in the form of buildings or goods and building them in such a way that the deconstruction of these valuable materials does not pose any difficulty. In this way, buildings would be interpreted as raw material deposits for future generations. However, to enable this transformation to a circular economy, a transitional state is needed that prepares the construction industry for the challenges of a circular economy and brings it closer, step by step.

Urban mining is a principle that closes precisely this gap, explains Dirk Hebel, architect and professor of design and sustainable building at KIT (Karlsruhe Institute of Technology). According to this principle, existing "raw material mines" are to be used, for example in the form of buildings. These "urban mines" can be exhausted in order to reprocess and use secondary raw materials for new buildings. The term secondary raw material refers to those materials that are recovered from recycled material, such as steel. This is in contrast to primary raw materials, which are taken directly from the source, such as sand or wood from forestry.

For construction to get one step closer to a true circular economy, the design concept of buildings must incorporate the end-of-life and materials have to be installed in a recyclable manner to ensure that the value chain is maintained. Currently, the concept of urban mining is proving to be challenging, as existing buildings and goods are not designed to be returned to the recycling loop at the end of their useful life. The currently prevailing straightforward economic model that proclaims, "take, make & waste" rather contrasts with the idea of recycling. Thus, irreversible compounds are created by bonding or mixing in the material flow, which are thus inseparable or can only be recycled at great expense. On this basis, the extraction of resources from anthropogenic space is an energy- and time-consuming undertaking.

Nevertheless, it is worthwhile. The president of the Federal Environment Agency, Maria Krautzberger states, that the material assets in Germany amount to around 50 billion tons. And this value increases by 10 tons per inhabitant every year. Thus, raw materials have been tied up in buildings, infrastructures, industrial structures and durable consumer and fixed goods over many years. These potentially represent immense benefit for future generations. Particularly for a country like Germany, which primarily imports raw materials due to a lack of resources, taking existing materials into account is a real gold mine in view of the scarcity of resources.

To ensure sustainable access to these resources, meticulous cataloging of the materials used in buildings is required. After all, not every building has the same suitability for recycling-oriented deconstruction.

Urban mining index – example of the Korbach town hall project

Dr. Anja Rosen from the University of Wuppertal developed the Urban Mining Index (UMI) in order to examine the recycling potential of buildings using quantitative methods and thus created the basis for a powerful planning tool for urban mining design. Thus, the UMI can be used to check which building materials are suitable in their condition for reuse or recycling in a later life cycle and how high the proportion of circular building materials is.

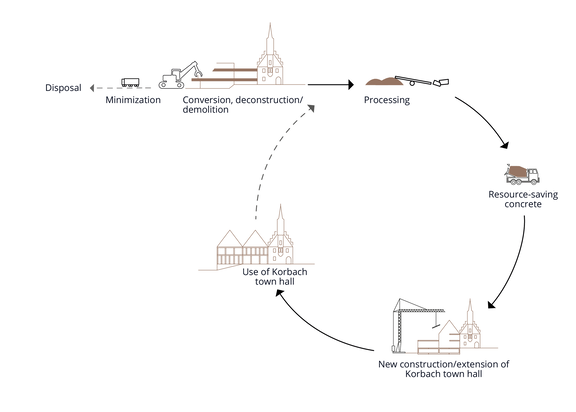

This method has already been applied to a pilot project. The historic town hall in Korbach (Fig. 2) is currently being renovated and a new extension is added, which is already in the process of completion. The project was planned and realized by the architectual office ARGE agn heimspiel-architekten, commissioned by the city of Korbach (Fig. 1). Anja Rosen developed the urban mining concept and analyzed and evaluated the project with the UMI during pre-design. The old extension, a concrete building from the 1970s, was used as a "raw material mine" by processing and recovering the demolished mineral building materials for the new building with the help of regional companies. The process had to be precisely planned and calculated to ensure a deconstruction with a clean separation of materials. Thus, the demolition was carried out highly selectively with the greatest possible consideration of clean material separation. With this process, about two-thirds of the demolished building materials could be returned to the material cycle in different quality grades - from the backfilling of the old foundations to the use in structural concrete and the facade (Fig. 3).

"We, as architects and engineers, are building today with the resources of future generations. To promote circular construction, we need to measure, evaluate and optimize circularity rates."

Dr. Anja Rosen - Initiator of the Urban Mining Index

Irreversible bonding or mixing of materials was avoided entirely in the project. The facade of the building will provide insight into the use of the recycled materials: The exposed concrete was blended with reclaimed mineral materials such as recycled aggregate and brick chips.

During construction, explicit care was taken to ensure that the building materials were combined in such a way, that they could be extracted with the same quality in the future and consequently represent benefit for future generations. With its cubature and recycled materials, the new building fits naturally into the urban context and is thus an important contribution to the preservation and continuation of the local architectural culture.

NEST - "Building the future together"

In Switzerland, the NEST (Next Evolution in Sustainable Building Technologies) opened in 2016 on the campus grounds of the Empa Materials Testing and Research Institute in Dübendorf. Since that moment, around 150 partners from the research and industry sectors have been working closely together to drive sustainable building innovations. Due to the practical application of new products on real projects, market entry times can be accelerated.

The modular structure of the NEST building is particularly noteworthy. The various research projects are housed in so-called box-shaped "units". After project completion, these can be moved within the stable building structure or replaced by new research units. This makes the building concept particularly flexible and adapts to the use of its occupants and research groups. With the modular NEST, a dynamic hallmark has been created on the campus that serves as an example of the diverse projects and manifold innovations of the research facility (Fig. 4).

In 2018, the research unit "Urban Mining and Recycling" (UMAR) was incorporated into NEST. The unit was designed by Werner Sobek, head of the Institute for Lightweight Design and Construction at the University of Stuttgart, together with Dirk Hebel and Felix Heisel, research officers for sustainable construction at KIT Karlsruhe. The module was prefabricated in a workshop and then transported to NEST, where it was deployed within one day using two cranes (Fig. 5). UMAR once again impressively demonstrates that recyclable building materials can be reconciled with architectural aesthetics. The wood used in the unit was installed in such a way that the standardized chemical treatment processes could be omitted, so nothing would stand in the way of later reuse or natural composting. Furthermore, copper plates that once adorned the roof of a hotel in Austria found a new use as part of the module's facade. In addition, the interior design of the UMAR is shaped entirely around the underlying premise of the circular economy: The materials used and the room inventory are completely reusable, recyclable, or compostable.

"The materials used are not consumed and then disposed of. Rather, they are taken out of their cycle for a period of time and later returned into it." - Dirk Hebel

For example, the thermal insulation in one of UMAR's bedrooms could be obtained through mycelia (fungi). In this process, biological remains from agriculture (such as leftovers from a corn plant or wood chips) and the fungal hyphae (root systems) are mixed together in a solution and then poured into a mold. After a few days of growing, the slab is heated to a high temperature and the organism dies. What remains is a fully functional slab that can be installed in the wall. Depending on the composition of the ingredients, the properties of the slab are also changed and can be customized for the building purpose (Fig. 6).

The preceding examples show that the processing of secondary raw materials represents a sustainable integral economic concept. In view of rising population figures in cities and the accompanying high demand for housing, urban mining will be a significant incentive for preserving materials that are already locally available and will provide the basis for sustainable material flow management.

"The continuing growth of the world's population and dwindling resources urgently require a change in the mindset of the construction industry. In the future, we will have to build with a lot less materials for a lot more people."

- Werner Sobek

According to the Federal Environment Agency, the techniques and potential for procuring materials from secondary sources are far from exhausted. Consequently, there are also opportunities here to develop concepts that promote a closed-loop circular economy through the use of interdisciplinary and systematic approaches. Thus, the knowledge gained from implementing projects based on urban mining design is invaluable for a circular economy in construction. In addition, the principle helps to increase the understanding of the value of all secondary materials and thus raise awareness of circular economy models.

In general, a paradigm shift will be necessary. And not only in the economy, but also in our culture. In the long term, this can create the basis for giving designers and construction planners sufficient incentive to also include the end of product cycles in their conceptions.