Why Go Through All This Effort?

Before diving deeper into the topic of data, we should take a step back and remind ourselves of the ultimate goal of BIM-compliant design. At its core, it revolves around two key questions:

• How can design stakeholders exchange information effectively and efficiently?

• How can machines take over repetitive tasks to accelerate the design process?

The answer is simple:

we need efficient communication that supports the process both digitally and model-based. The shared building model serves as the foundation for consolidating information from various project stakeholders and streamlining workflows. The goal is to establish a common language for all participants—structured in a way that enables modern software solutions to offer automation. Ultimately, the key lies in the data that all stakeholders contribute to the process.

Digital Waste – The Importance of Structured and Quality-Checked Data

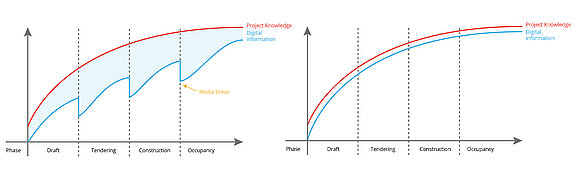

Data quality is at the heart of a successful BIM process. Data must be consistent, accurate, complete, unambiguous, up-to-date, and in the right format. However, in practice, problems frequently arise.

For example, importing architectural 3D models into CAD systems for data analysis (e.g., geometry or building physics) often delivers inadequate results. As a result, MEP designer often inevitably revert to traditional methods and prefer to create their own 3D energy models rather than waiting for a building model generated by a third party. This leads to duplicate work, additional effort, and an increased risk of errors. Looking further into the process, this issue often persists: Bills of quantities are not derived from the digital pipe or duct network topology but instead created manually. Execution and assembly design is carried out again due to impractical prior planning. Data required for building operation is manually re-entered into FM systems, despite already existing in digital form.

This digital waste reduces efficiency and strips the BIM process of its key advantages. An efficient BIM process requires more than just scaling existing software solutions for 3D modeling and equipping them with standard interfaces like IFC. To make the most of the available project knowledge, we must be able to interpret, organize, and validate incoming data. This process also needs to be administratively controlled to ensure reliable access to data for all stakeholders.

Data Interpretation

A key approach to optimizing data processes is LINEAR’s Parameter Manager. With LINEAR software, project-specific requirements (e.g., AIA/BAP), standards, and external parameters can be efficiently mapped and managed. Once set up, project participants no longer need to worry about where specific data belongs. This ensures:

Consistency: Uniform data structures for all project stakeholders.

Flexibility: Office standards can be applied and harmonized across multiple projects.

Another example is the classification function in the LINEAR Analyse products, which categorizes components (e.g., washbasins, toilets) and provides relevant technical data for calculations. This is particularly useful when working with content from a third-party or custom-built families. A single, one-time assignment is all it takes to make these families available for all calculations. Read more in the article "MepClasses – Precise Classification for MEP Components".

Data interpretation also plays a crucial role in ensuring that external project participants can efficiently use the generated results. However, IFC exports often pose a challenge. MEP components are frequently insufficiently categorized (i.e. as generic IfcBuildingElementProxy). To address this, LINEAR provides a precise classification system, structuring component groups in much greater detail. Automated suggestions for the correct IFC class assignments are based on accumulated design data, significantly reducing manual effort.

Organizing and Validating Data

What use is all the data collected if it cannot be structured and validated? Unorganized or faulty information creates no foundation for efficient work – it leads to uncertainties, additional work, and potential design errors. And more importantly: In complex projects, it’s not just about having all the data available, but also about being able to see only the information actually needed at the critical moment. A clear structure and targeted validation are therefore essential to not only make data available but also usable. They form the basis for smooth processes and successful collaboration among all participants.

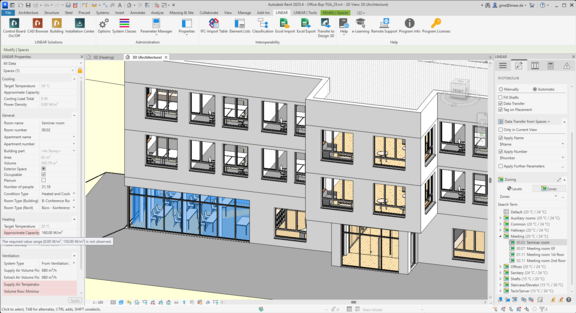

With the features "Element Classes and Property Sets", LINEAR offers a comprehensive solution not only to control the view and scope of the data in the properties field but also to validate it for quality. While Revit only allows the grouping of certain properties, we take a crucial step further: We enable a direct quality check of the data included. By defining valid ranges or setting specific value limits, we minimize the risk of faulty or inaccurate data entering the model. For example, minimum and maximum values for properties can be set, or only predefined selection options can be made available.

These functions are especially important in collaborative processes, as they ensure that data is entered consistently and standardized. This significantly improves the overall quality of the information in the model. Additionally, LINEAR allows for flexible adaptation of the Level of Information Need (LOIN) and administrative control over this process.

Once the data is organized and validated, numerous opportunities for evaluations arise. Overviews, such as default settings for valves or lists of flow rates and discharge times, can be created precisely and directly coordinated with the client. Moreover, LINEAR enables the export and import of parameters via Excel, allowing for information exchange with project participants without requiring a CAD system.

In this regard, the IDS format from buildingSMART presents a promising approach. Project and data requirements become machine-readable, making them usable for all participants. This allows for data validation in the respective authoring software during both import and export. While there are initial developments for coordination software capable of validating IDS requirements, there are currently still no solutions that link IDS structures directly to authoring systems such as Revit. LINEAR will provide a solution with a new assistant for this that enables easy integration and ensures the seamless use of data in the context of established exchange standards. If you’d like to learn more, check out the full content of our blog.

Efficient Workflows and Automated Processes

Modern software solutions for MEP design must go far beyond supporting traditional processes like design and calculation. They should provide solutions that promote interdisciplinary exchange of concepts and design results. LINEAR has long pursued this approach, aiming to make all data in the process usable. To achieve this, we have developed our solutions with a focus on the aspects mentioned above. That way, we can close gaps that lead to digital waste. Here are some examples of digital efficiency that we would like to present to you:

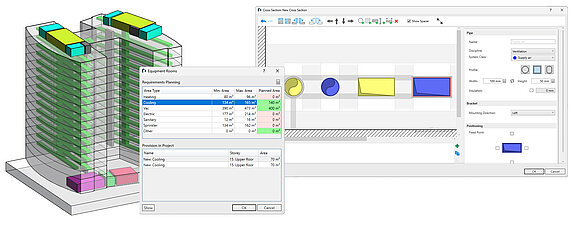

The LINEAR Pipe Route Concept

A typical problem is insufficient space in architectural models for mechanical rooms or media conduits. The cause often lies in poorly organized coordination processes and the lack of suitable digital tools. This is where the LINEAR Pipe Route Concept for Revit comes into play, enabling an interdisciplinary workflow. Based on "Provision for Voids," mechanical rooms and pipe route systems can be conceptualized with minimal effort. It is sufficient to define the gross floor area of the building and the general use concept (e.g., office, retail, large kitchen) to determine the space requirements. This is complemented by functions for dimensioning the pipe routes and their cross-sections. The result is a three-dimensional pipe route model that minimizes spatial conflicts and serves as the basis for automated media routing design. Instead of reacting to the spatial conditions provided by the architectural office, MEP design can already transmit space requirements in a model-based manner at the beginning of the process. This early influence then saves time-consuming discussions and extensive redesign in the following phases.

To further make use of the early work and avoid digital waste, the pipe routes, with all the information they already contain (pipes, media, dimensions, etc.), are then used to generate the corresponding pipe systems. This forms an ideal basis for further construction.

Load Calculations for Heating and Cooling

As mentioned earlier, the use of the architectural model for load calculations is often limited by the model provided, as in many cases, only 2D plans are available or the necessary geometric and thermal component data are incomplete. This forces the MEP designer to create a separate energy model — a double effort with increased risk of errors. In this case, MEP design essentially intervenes in processes for which they are not responsible. The LINEAR building analysis solves this problem by analyzing both Revit and IFC files and deriving a thermal model from them. In addition to the necessary in-depth analysis of complex models, this solution is also capable of analyzing "unclean" architectural models and using them as a basis for load calculations. It checks for faulty data, which can then be manually added or adjusted.

The results of the load calculations — such as calculated radiators or surface systems — can be directly transferred into the building model, providing all relevant parameters for further planning. Any changes in the architectural model are automatically considered and updated, accelerating the design process and avoiding errors.

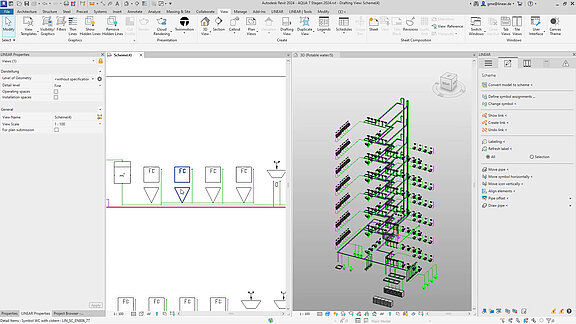

Automatic Scheme Generation

Another example of increasing efficiency is the automatic creation of schemes based on a 3D Revit model. In the created 3D model, all the data needed for creating a scheme is already present. It would be digital waste not to use this data and instead create a separate scheme, even though it could be linked with the components in the 3D model later on. Digital efficiency in this context means generating the scheme automatically based on the 3D model. The LINEAR scheme essentially serves as an alternative view of the pipe network. All components of the pipe network are interconnected in the views, ensuring that the data foundation is consistent.

These are just three selected examples to demonstrate that digital efficiency is achievable. Other process steps, such as slot and opening design, execution and assembly design, or the creation of regular plans, are also supported by LINEAR’s efficient solutions and have been thoroughly discussed elsewhere.

Conclusion

Digital efficiency gives you access to a wealth of valuable data and is thus the key to increasing profitability and quality of your design. LINEAR offers a well-thought-out workflow and comprehensive features for Revit, providing an ideal solution to optimize digital processes in MEP design. This enables interdisciplinary collaboration that meets today's BIM requirements.