![[Translate to Englisch:] Berufsfachschule für Musik in Plattling](/fileadmin/_processed_/5/e/csm_Kermi_Titel_a68165e206.jpg)

Despite long continuous supply pipes, the large corridors were not to be heated in an uncontrolled manner, but were to be individually controllable. At the same time, an improved impact sound insulation had to be realized. With the Kermi x-net connect plus connection system, the client opted for a solution that optimally met both requirements.

With the foundation of the Vocational School for Music by the city of Plattling in 1977, a new type of school was created in Bavaria. Since then, this type of school has offered, among other things, a vocational training to become a musician at technical college level, qualifies students for further studies at music colleges and offers additional pedagogical qualifications. The Vocational School for Music Plattling, the oldest of its kind, was able to move into a modern school building, which it shares with the Academy for Social Pedagogy. Synergy effects in the use of different rooms are thus optimally used. From the outside, the colored louvers of the new multi-story building in Plattling’s Nordpark quarter are visible from afar. Inside, around 180 adult students now learn in rooms of different sizes with differently designed walls, as well as in the multifunctional foyer.

Supply pipes through long corridors without loss of comfort and efficiency

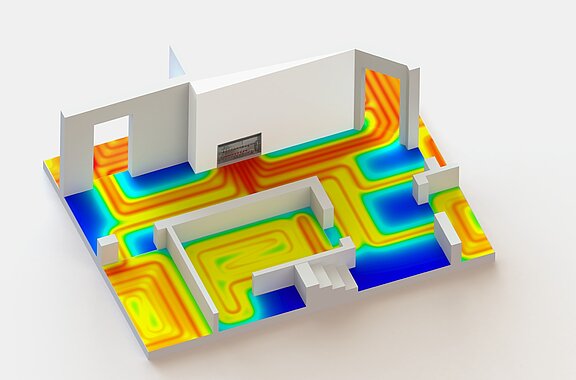

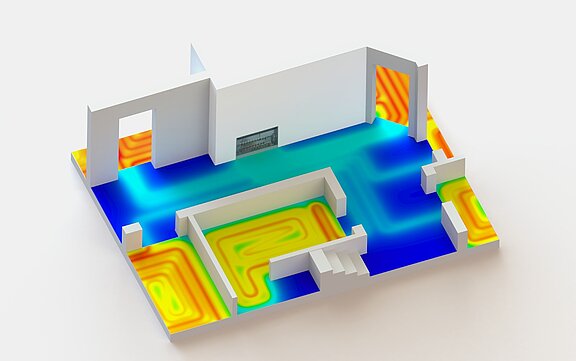

An efficient panel heating system was to ensure pleasant temperatures in this new building. Meanwhile, one challenge in planning this heating solution was the long and large corridors. Here, the following problem usually arises with panel heating systems: The supply pipes which convey the heating water from the distribution cabinets mounted in the corridor area to the heating circuits of the individual rooms give off an uncontrolled amount of heat via the screed in the corridor. This leads to an undesired heating effect or overheating of the corridor and thus reduces not only the comfort but also the efficiency of the heating system. Especially in schools, acoustics and sound insulation also play a decisive role in the planning - among other things, the impact sound from the corridors had to be explicitly taken into account.

GEG-compliant solution: Routing the heating pipes under the screed

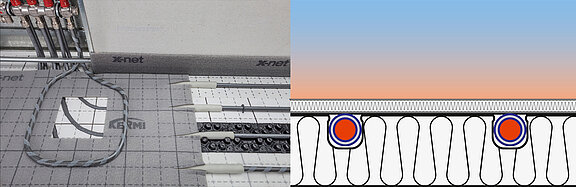

After competent consulting by the specialist company Bad und Heizung Krampfl GmbH in Plattling, x-net connect plus in combination with the x-net C12 tacker system was selected for the property and the installation was commissioned. Ernst Schwaiger, technical project lead at Krampfl, explains: “The x-net connect plus connection system was the ideal solution for this case. It enables individual temperature control, especially in the long corridors of the school building. In this way, the requirements of the GEG (German Building Energy Act) are met, which prescribes an individual control for all rooms with more than 6 m² of usable floor space. At the same time, the system’s very low dynamic stiffness has an enormous impact sound-absorbing effect, thus minimizing unnecessary acoustic disturbances.” The uniqueness lies in the installation: Instead of embedding the continuous supply pipes to the individual rooms in the screed, these first lead from the manifold into an insulating layer under the screed and only dip into the screed level at the rooms to be heated. Accordingly, the heat from the heating system is conducted systematically under the screed, thus preventing undesirable heat emission. The insulation values achieved in this way cannot be realized in building practice with a pipe conventionally embedded in the screed and sheathed with pipe insulation - due to the additional screed thickness required.

The components: effective impact sound insulation, high sound protectionThe system from Kermi consists of two components: the EPS system panel x-net connect base and the cover element x-net connect cover. Together, they have a high impact sound-reducing effect even with a narrow arrangement of the supply pipes, corresponding to the effect of an “EPS DES sg” insulation board installed in the conventional manner under the screed. For increased sound insulation requirements, Kermi supplemented the x-net connect plus as type “EPS DES sm 35-3” with an impact sound reduction of 33 dB in 2018. This also allows the strict requirements for sound insulation according to VDI 4100 to be met. Depending on the structural conditions, the x-net connect system can be combined with different x-net systems of panel heating/cooling from Kermi.

Installation: Fast, simple, practical

The entire installation was carried out under the direction of the company Krampfl together with the Kermi installation service. On request, the service supports the specialist tradesman during the installation of the x-net panel heating/cooling system, for example in the event of staff shortages. “Thanks to the cooperation with the Kermi specialists, the work could be carried out quickly and precisely. For us, the installation service is a clear advantage, especially for large objects and overlapping deadlines, in order to fulfill our absolute demand for reliability as the commissioned and responsible specialist company,” Ernst Schwaiger sums up.

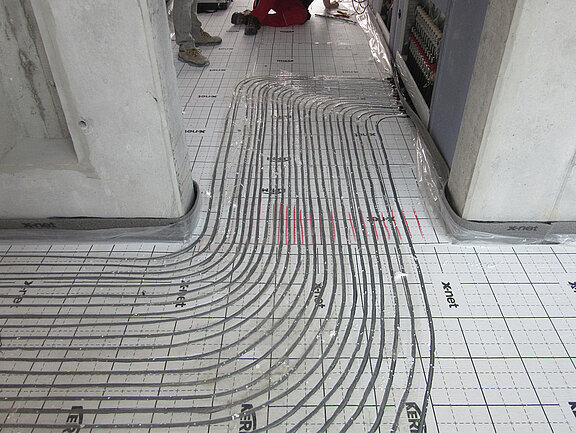

After installing the x-net distribution cabinets, the installers laid a total of around 2,000 m² of the x-net C12 tacker system in the classrooms, and 600 m² of the x-net connect plus system was used in the corridors. In the special EPS insulation board, the x-net connect hot cutter with double cutting tip made it easy and efficient to create the pipe channels for the supply pipes and to lay the pipes up to the start of the heating circuits in the rooms.

The second component of x-net connect plus, the six-millimeter-thick cover element x-net connect cover, was then applied over the full surface of the continuous supply pipes in the corridors, and thanks to the self-adhesive backside, installation generally proved to be simple. The top side with its hook-and-loop fastener in turn provides a surface for quick, tool-free installation of the x-net PE-Xc pipe with hook-and-loop fastener - and thus for forming the heating circuits in the corridor and transition areas that can be controlled separately. During installation, x-net connect convinces as a unique, tested overall solution including a safe and screed-water-tight threading of the continuous supply pipes from the insulation level into the screed level - for perfect sound insulation and standard-compliant installation. A total of approx. 16,600 m of x-net PE-Xc pipe was installed in the building.

In this building, several distribution cabinets are located in separate connection rooms. Accordingly, no separate heating circuit is required here. But due to the many heating circuits in the large corridors, it was necessary to ensure that no heat was lost here and that no overheating occurred. Also, x-net connect plus offers the solution for this requirement: The pipes with hook-and-loop fasteners for the corridors were embedded in the x-net connect base plus panel analogously to the supply pipes to the individual rooms. The entire area in the connection rooms or in front of the distribution cabinets was finally covered with x-net connect cover. This ensures maximum insulation in the connection rooms and prevents unwanted heat emission.

Comfortable warmth for all students

Within a very short time, it was possible to install an floor heating system that was optimally tailored to the requirements of the vocational school. Principal Roswitha Artmeier also confirms this: “In the first winter months, we had comfortably warm temperatures exactly where we needed them. The overall sound insulation in the building is also excellent - our students can practice undisturbed in all rooms.”

Ernst Schwaiger confirms likewise: “The installation of the heating components worked flawlessly - quickly, easily, and optimally suited to the object. The client, i.e., the administrative district of Deggendorf, even called this his “favorite construction site” - simply because everything was solved in a technically excellent way and worked perfectly according to schedule. As the specialist partner jointly responsible for this project, we are of course very pleased.”

Planning support with LINEAR

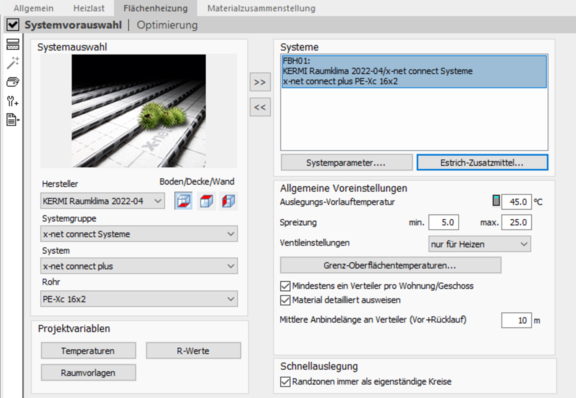

Kermi also offers its planning partners planning support for the complete panel heating and cooling system from the experienced specialists in Kermi application technology.

The proven software from LINEAR has been used for many years. The Kermi products, such as the systems mentioned, are available as a data set for direct use within the software (see Fig. 10). This allows the actual technical advantages, such as reduced heat losses, mass flows, pressure losses, etc., to be included in the calculation and thus in the efficiency of the overall system.

Two problems, one solution

With x-net connect, Kermi was the first manufacturer to launch a connection system for panel heating on the market in 2016, which allowed the implementation of individual room control - as required by EnEV at the time and by GEG today - in passageways with continuous supply pipes. In addition, the loss of valuable heat in the continuous supply pipes is avoided.

Figs. 11- 14: Despite long continuous supply pipes, the large corridors of the Vocational School of Music in Plattling were not to be heated in an uncontrolled manner, but were to be individually controllable. At the same time, increased impact sound insulation had to be implemented. With x-net connect plus, both requirements could be optimally met. (Images: Kermi)

Since then, x-net connect, together with a version for increased sound insulation added in 2018, has proven itself as a structurally safe and, above all, easy-to-install solution: Over 25,000 apartments and a large number of commercial buildings have since been equipped with the system - for efficient and controlled heating operation.

Kermi GmbH

Pankofen-Bahnhof 1

94447 Plattling

www.kermi.com