The S-Bahn Academy in Munich, which will be completed in October 2025, plays a key role in the programme of the 1st Munich S-Bahn contract at S-Bahn München. It will be used for further and advanced training as well as for training S-Bahn drivers. With five special simulation rooms (virtual train driver's cabs), 15 training rooms and three group work rooms, the academy offers ideal training conditions.

In addition, overnight accommodation is available for participants to ensure maximum comfort. An architectural highlight of the building is the open staircase in the entrance area, which spans several storeys and can also be used as an event venue.

Partnership and design with state-of-the-art technologies

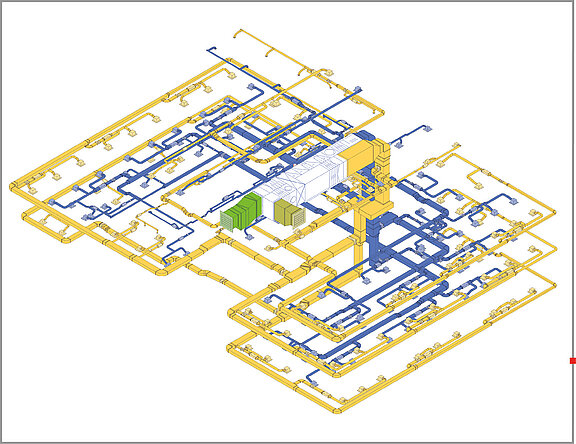

In close collaboration with our partner Quadra Ingenieure, we were able to develop and significantly shape this construction project from the very beginning. The interface-free design in Revit (closed-BIM) ensured a high level of cost certainty at an early stage and enabled the integration of customised building technology. Our extensive experience with Revit, which we have gained together with Quadra Ingenieure over the years, contributed significantly to the success of the project.

Thanks to the joint processing in Revit, we received all relevant information such as geometry, component properties and spatial data directly from the architectural model. This could then be analysed directly with the LINEAR software and served as the basis for the entire building services design. This approach meant that everyone involved in the design process benefited from a holistic BIM model. This meant that the design of the technical building equipment could be viewed directly in the model and taken into account accordingly, which in turn enabled dynamic adaptation of all design in the process. Particularly noteworthy is the uncomplicated and fast coordination process for openings, which could be implemented precisely and smoothly thanks to LINEAR openings design.

Sustainable solutions for heating and cooling

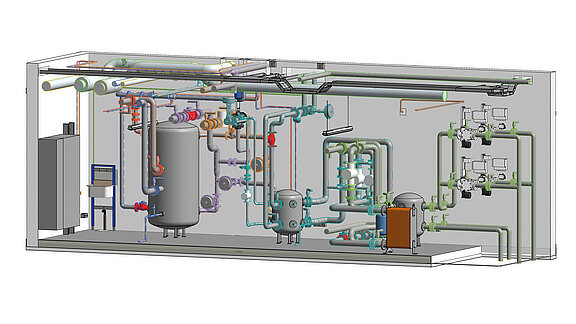

The client required a sustainable energy supply, which was realised using a brine heat pump fed from the groundwater via extraction and absorption wells. This technology offers flexibility for both heating and cooling the building. In transitional periods, free cooling via a bypass allows the groundwater temperature to be utilised without using the heat pump. In this case, the energy used is limited to the auxiliary energy of the pumps. For separate heating and cooling circuits and for storage, a heat and cold storage tank have been integrated into the centre.

The hot water supply is decentralised via instantaneous water heaters. This solution, which is adapted to user behaviour, ensures drinking water hygiene on the one hand and eliminates the need to store water above 60 °C in the buffer tank on the other. This allows the generators to operate efficiently at their optimum output range.

Efficient and comfortable building technology

A surface heating and cooling system was chosen for the distribution of heating and cooling, which offers additional efficiency benefits thanks to the low temperature levels in the system. The building is also fully ventilated and aired, with the focus on effective heat recovery and designing the heating and cooling registers for low temperature levels. The concept is complemented by comprehensive LED lighting with presence control.

A central building management system (BMS) networks all technical systems and allows them to be controlled on site or remotely as required. This ensures a high level of efficiency while maximising user comfort at the same time

Optimum use of design tools

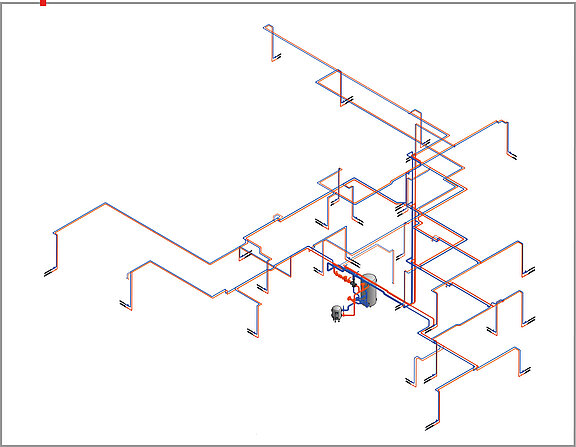

The full potential of the LINEAR solutions in conjunction with Revit was utilised in the design process. The heating and dynamic cooling load calculation as well as model-based pipe network calculations for drinking water and waste water, heating and ventilation were carried out in stages.

Firstly, the building envelope, cubature and component information were read out of the model, checked and added to. Air volume calculations, which were included in the heating and cooling load, were determined manually and transferred to the model. These could then be taken into account in the LINEAR calculations. This iterative working method makes it possible to identify input or modelling errors at an early stage, thus saving valuable time.

The pipe and sewer network calculations followed a similar principle: After a rough pre-dimensioning in the course of the route concept in service phase 2, the components from producers and consumers were then detailed and integrated into the model. Neutral Revit families or "dummies" were initially used for the generators, which were replaced by the actual manufacturer products in later service phases. In the event that not all the final information on the consumers was available, we temporarily used components such as the LINEAR "string end", which we stored with the corresponding performance data.

The LINEAR pipe network calculations offer particular help here, as they allow all components to be freely configured. For example, self-created solids can also be integrated into the network as consumers or generators. As soon as the network has been designed with the essential components, the pipe networks can be calculated and errors quickly identified. Design errors are visualised clearly and simply directly in the model. Thanks to many years of experience, errors within the calculation can also be successively resolved using the model. Finally, we redimension the pipe network and transfer the checked calculation data such as dimensions, mass flows and velocities to the model.

This step-by-step procedure gives us certainty in the dimensioning at an early stage, as lengths and height jumps are always checked against the actual design and, unlike in 2D design, sources of error such as connection points or partial section lengths do not have to be checked retrospectively.

Success factor: collaboration and innovation

The successful realisation of such a complex project requires not only innovative technologies, but also close coordination between all parties involved. The selection of suitable software tools such as Revit and LINEAR as well as a well thought-out model exchange were crucial in order to carry out the design efficiently and smoothly.

Heimann Ingenieure can look back on almost 40 years of company history. We continuously rely on the latest technical developments and innovations, particularly in the field of hardware and software, to optimise our design processes. With over 90 employees in Berlin and Heppenheim, we provide comprehensive design services in all areas of technical building services.

Heimann Ingenieure GmbH

Köpenicker Straße 9

10997 Berlin

Further information is available at:

www.heimann.de