In times of ever-increasing demands on energy efficiency, living comfort and building cost control, serial renovation is proving to be a real game changer. This innovative approach offers designers and companies a new perspective for the energy transformation of existing buildings – especially with regard to the efficient, economical and sustainable implementation of extensive renovation projects. Digital design, industrial prefabrication and standardised processes allow projects to be completed in a short time and with a high degree of precision. And even in an inhabited state.

The Berlin-based company ecoworks has developed a process that allows buildings to be transformed into climate-neutral properties within just a few weeks. All project phases are bundled into an integrated process. The high degree of prefabrication shortens the construction time and minimises disruption, ensures quality and at the same time creates the basis for ESG-compliant, future-proof buildings.

The serial renovation of a residential complex in Bochum

A successful example of this is the serial renovation of a residential complex in Bochum, Germany. As part of the pioneering renovation project, three apartment buildings from 1965 with a total of 18 residential units were extensively modernized. The aim of the measures carried out in 2023 was to bring the buildings up to the KfW55 EE standard in terms of energy efficiency through serial renovation (a German energy efficiency benchmark requiring buildings to use only 55% of the energy of a comparable new building), thus drastically reducing energy consumption and making a further contribution to climate-neutral building stock.

The biggest challenge of the project in Bochum was the exact inventory and the standardization of design processes in order to enable a high degree of prefabrication of the building elements. Different building standards and individual interventions by tenants over the decades initially made standardization considerably more difficult. The integration of modern technology such as ventilation systems with heat recovery or panel heating systems also placed high demands on the design and coordination of the trades.

Thanks to the systematic approach, numerous advantages were realized:

- Cost certainty: Design and construction costs were reduced thanks to prefabrication and repeatable modules.

- Time savings: The renovation time per unit was halved thanks to the serialized approach.

- Quality: The use of standardized components increased the quality of execution and reduced defects.

- Sustainability: Thanks to improved insulation, intelligent building technology and renewable energy sources, the primary energy requirements of the buildings were reduced by over 60 %.

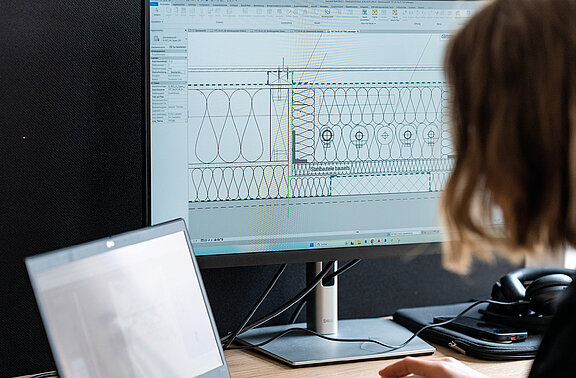

A key element in the project's success was the use of LINEAR software solutions. In particular, the combination of LINEAR Building and integration in Revit enabled fast and precise design:

- The as-built survey was digitized and converted into parametric building models.

- Recurring components and MEP modules were standardized in LINEAR and stored as templates.

- The software enabled the simulation-based design of the heating, ventilation and sanitary systems, including hydraulic balancing.

Without the software solutions from LINEAR, such a high degree of standardization and precision would hardly have been possible. The strength of digital tools is particularly evident when designing technical installations in modular systems.

The holistic process of serial renovation at ecoworks

Project development, property and cluster analysis

First, the potential in the property portfolio is examined: ecoworks provides a free cluster analysis. AI image recognition via 3D satellite data enables the evaluation of postal addresses. Here, ecoworks evaluates the properties and calculates a scoring. The aim is to use the building criteria to find certain typologies that recur in the portfolio in order to quickly and easily develop the ideal serial renovation strategy together with the customer.

Digital design: from a 3D scan to the digital twin

ecoworks uses Building Information Modelling (BIM) to make the entire renovation process much more effective. BIM helps to standardize and automate design, production and execution. The facade and roof elements, pipework and other building components to be produced in the factory must be designed and manufactured to fit the existing building precisely. The starting point is a three-dimensional, millimeter-precise measurement of the building's condition by laser scan and a point cloud created from this. With the help of this point cloud, the 3D building model is created as a digital twin of the building. This model forms the basis for fast and cost-efficient design and execution of the renovation project.

Production: Production in the factory

With prefabrication, ecoworks shifts up to 80 % of the work from the construction site to the factory. This makes renovation capacity available and construction times can be significantly reduced. The facade modules manufactured in the factory already contain insulation, windows, summer heat insulation and controlled ventilation systems. In addition, a large part of the required building technology can be integrated into the facade as required. A scalable and available solution requires strong supply chains. The partners of ecoworks are among the largest timber construction and prefabricated house builders in Europe. With their help, short logistics routes to all federal states are guaranteed.

Assembly on site

The finished facade and roof elements, as well as a photovoltaic system and an air-to-water heat pump are assembled on site within a few weeks. ecoworks works with specially trained teams to ensure the highest quality and reliability. The high degree of prefabrication enables tenant-friendly renovation while the building is occupied.

Building operation: climate-neutral operation

Prefabrication in the factory brings considerable quality benefits to reduce future operating and maintenance costs. In addition, ecoworks achieves demonstrably higher energy efficiencies in operation, from low-temperature capability to the NetZero standard. When NetZero requirements are met, the building is considered greenhouse gas neutral. The buildings can then generate the energy required for heating, hot water and household electricity themselves in the post-renovation state.

Summary

Serial renovation: A blueprint for climate-neutral building stock – with the help of LINEAR software

The pilot project in Bochum is far more than just a successful individual example. It impressively illustrates how the housing industry can systematically and economically tackle the huge challenge of modernizing the energy efficiency of its portfolio. Experience shows that the path to a climate-neutral building sector does not necessarily have to involve lengthy and cost-intensive individual measures, but can be designed and scaled through the intelligent combination of digital design and industrial prefabrication.

The renovation of the three apartment blocks from the 1960s to the demanding KfW55 EE standard proves that serial approaches work in practice. The key insight lies in overcoming the complexity of the existing building stock through an end-to-end digitalized process. The initial hurdles, such as inconsistent building conditions and individual adaptations that have evolved over decades, were overcome thanks to a precise digital building twin. This twin, created on the basis of 3D laser scans, forms the foundation for the customized industrial production of facade and roof elements. Software solutions such as those from LINEAR are no longer mere aids here, but the backbone of the entire design project, which enables a standardized and low-error MEP design in the first place.

A clear conclusion can be drawn from this for the housing industry: shifting a large part of the added value from the volatile construction site to the controlled environment of the factory solves several core problems at once. It counters the shortage of skilled labor, significantly increases the quality of execution and reduces the construction time on site to a minimum, which makes renovations in an inhabited state much more tenant-friendly. The process demonstrated in Bochum, from AI-supported portfolio analysis to BIM design and rapid assembly, provides a strategic answer to the pressing issues of cost certainty, speed and sustainability. This transforms serial renovation from a niche technology into a central, tried-and-tested tool for the sustainable development of the entire housing stock.

As a general contractor for serial and sustainable building modernization, ecoworks focuses on solving key challenges in the housing industry. The interdisciplinary team from the fields of engineering, architecture, energy consulting and digitalization combines many years of industry experience with a shared passion for innovation. Thanks to digital design and industrial prefabrication, 80% of the added value is shifted from the construction site to the factory. In this way, ecoworks realizes renovations that are not only fast and economical, but also demonstrably successful.

For more information, please visit: ecoworks website