Update on the status of the municipal heat planning in Germany

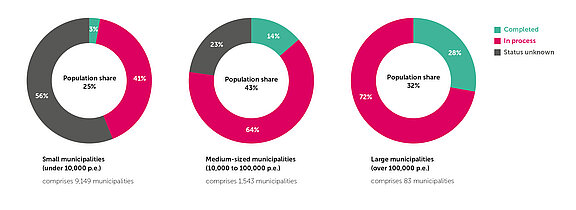

Almost half of all local authorities in Germany are already involved in or in the process of drawing up a municipal heat plan (KWP). And more than 500 local authorities have already completed the KWP(1). There is a clear disparity between large cities (municipalities with over 100,000 inhabitants) and medium-sized and, above all, small municipalities (diagram 1).

Once the heat plan has been finalized and published or approved by the city or municipal council, the actual work begins with regard to the concrete implementation of identified measures. This means that after the municipal heating plan is before the district heating network design and the realization of these networks. Heating network (priority) areas are identified in heating plans. These can be large local or city (sub)networks or smaller clusters at neighborhood level.

The fact is: there are many new heating networks and there will be many more. This raises the question: Who will design these networks? What specific challenges are there? Are suitable design tools available?

Let's take a look at what this actually involves. As part of the KWP, an initial, usually still very rough, network concept is usually drawn up, including an indicative network calculation based on the determined heating requirements and taking into account the development of demand due to possible refurbishment of the buildings. The supply concepts take into account the regionally economically viable renewable energies, including the potential of unavoidable waste heat. The results obtained here generally form the basis for subsequent network designs(3). The next steps are as follows: Preparation of a feasibility study, e.g. subsidized by the Federal Fund for Efficient Heating Networks (BEW), with service phases 1-4 according to HOAI

(= module 1 of BEW)(4). This work is carried out by engineering and design offices, engineers at municipal utilities and contractors and is widely supported by system manufacturers such as REHAU(5). In the course of this work, the district heating network takes on more and more shape, concrete challenges and the possible complexity become clearly visible. The results of the study then provide a basis for decision-making so that – if the results are positive and the decision is made by those responsible – implementation can begin. Based on the current BEW funding system, this means applying for Module 2 and starting the construction design

(service phase 5).

Concrete challenges in the Design of district heating networks

An (initial) cost estimate is already required as part of the concept development process. This involves evaluating which factors significantly influence the costs. Focussing on material and processing, the question arises as to whether and to what extent plastic jacket pipe systems (KMR) with steel media pipes or polymer pipe systems (PMR) with PE-Xa media pipes can be used, possibly also in combination. The fact is that the use of PMR is becoming increasingly interesting for many municipal utilities as builders of new networks, as these system solutions are quick and easy to plan and install, with a significant cost-saving potential of up to a third(6). It is also clear that the complexity of projects is increasing significantly across the board. One example is the consideration or integration of several heating supply systems based on the local sources of renewable energy identified as part of the KWP. In addition, expansion plans and the subsequent integration of green heat and power generation plants must be taken into account in order to ensure sustainability. And: project development and design is becoming increasingly dynamic. Flexibility is therefore required to be able to react in a targeted manner to frequent short-term changes to the boundary conditions in the planning process. One example of this is the selection of locations for heat sources. If locations are changed during the design process, this usually means a complete recalculation of the network hydraulics with corresponding effects on costs. A supposedly often underestimated aspect: securing the budget framework through precision, depth of detail and transparency in the design. This involves the feasibility of network construction through the integration of component libraries in order to avoid problems during subsequent implementation. The flexibility of PMR can make a significant contribution here with regard to the design and construction of new networks for existing buildings. In the event of unforeseen underground construction situations, for example, a solution can be found quickly and cost increases can be avoided or at least kept to an absolute minimum.

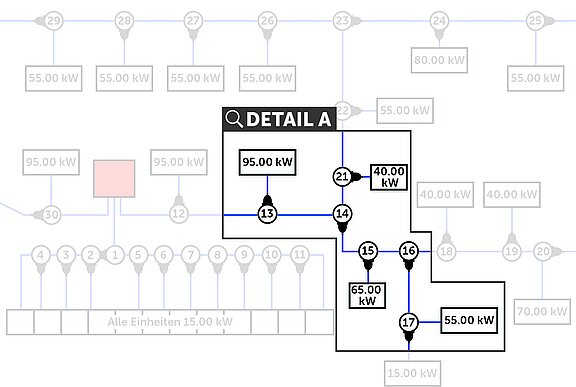

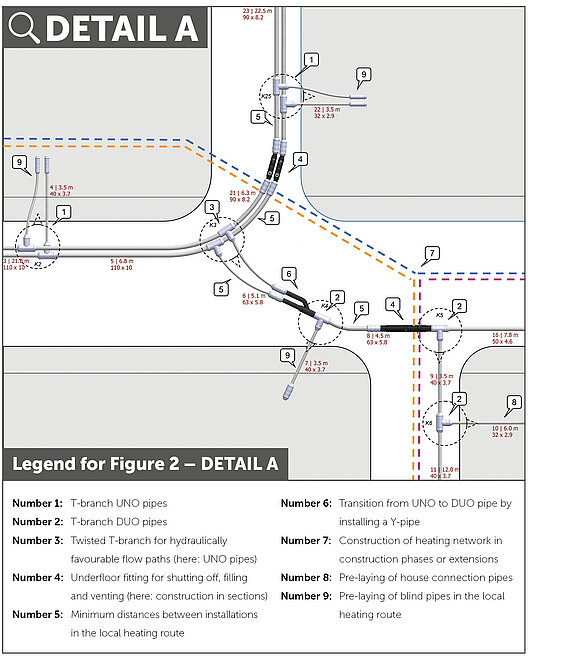

Figure 1 shows an example of a district heating network design with the simplified representation of a branch situation that is very common today. The level of detail is limited to the basic routing with the branches (junctions) and house connections. In terms of feasibility, however, this design is still inadequate. For the marked network section “Detail A”, Fig. 2 shows how, taking into account the use of PMR with the appropriate components (including the transition from two single pipes to a double pipe by means of a so-called Y-pipe), the ready-to-implement representation can look in principle. Powerful design software should come as close as possible to this level of detail in the future.

Of course, the focus is also on precise network hydraulics. Maximum efficiency is a “must-have”, oversizing and unnecessary (“hidden”) reserves must be avoided in order to ensure economical network operation in the long term. This includes, among other things, calculating the diversity factors for each individual piping route section and consequently minimizing the pipe size on the basis of the damping effect of the diversity factor.

In addition, it must be possible to quickly and easily analyze supply and network expansion scenarios in terms of their impact on the design. For example, it is necessary to analyze what happens if a ring closure or meshing of the network takes place. What effects does this have on the security of supply in the context of integrating several heating distributors? Equally important are calculations for a changed connection rate with regard to pipe dimensioning that makes economic sense in the long term. The geodetic heights also play a decisive role in the dimensioning of such networks and have an influence on the calculation of the maximum pressures.

Software solutions for network design – Status quo and outlook

There are already a number of software solutions for development of district heating networks. New tools have been developed in recent years, particularly in the context of the KWP, which deliver good results quickly, especially in the early project phase. However, these solutions are more or less limited and often not suitable for processing up to the construction stage. Against this backdrop, a new digital solution is currently being developed through a collaboration between LINEAR and REHAU, drawing on decades of experience in heating network design. This solution is based on the established AutoCAD system platform. With the implementation of a comprehensive and very powerful new design and calculation module, the result for users will be THE SOLUTION for sustainable district heating network design. The range of applications covers all relevant areas:

- Neighborhood concepts for new and existing buildings

- Larger district heating networks in municipalities and cities

- From the first draft to ready for installation

- Network expansion and network extensions

A selection of features:

- Calculation of ring and mesh networks

- Consideration of multiple energy or heating centers incl. automatic recalculation in the event of a change of one or more locations

- Consideration of the geodetic heights in the network

- Comprehensive component library

Heating networks, as shown in Figure 3, can be professionally processed up to the construction stage in the future. The new solution will be available from the beginning of 2026 and will make a substantial contribution to speeding up the design of district heating networks overall. If you are interested, you have the opportunity to view the first preview at the HEATEXPO from 25 to 27 November in Dortmund at the REHAU stand 4.D52. We, the LINEAR and REHAU team, look forward to your participation and visit. Would you like to take advantage of an exclusive presentation at HEATEXPO? Then simply make an appointment with us:

Contact

Astrid Welss

astrid.welss@~@rehau.com

About the author:

Dipl.-Ing. (FH) Olaf Kruse

Senior Product Engineer

& Project Manager District Heating

REHAU Industries SE & Co KG, Erlangen

Contact:

REHAU Industries SE & Co. KG

Ytterbium 4

91058 Erlangen

Tel.: +49 9131 92-5346

E-Mail: Olaf.Kruse@rehau.com

gebaeudetechnik.rehau.de

Olaf Kruse has been working in the energy supply industry since 1995, initially in the field of consulting and design, specializing in geothermal systems. In 2004, he moved to the industry, joining polymer specialist REHAU with responsibility for the product development of solar thermal systems and potable water heating systems. Since 2013, he has been contributing his extensive experience as a product engineer and project manager to district heating projects throughout Germany.